Choose the right peanut oil extraction machine - A buyer's guide

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 100T-300T/D

- Voltage: 220V/380V

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W): depends on capacity

- Country: lagos

Peanut oil making processes and processing machinery Peanut oil is an extremely popular edible oil because of its stability, low viscosity and slightly nutty flavour. It has a relatively low concentration of polyunsaturated fatty acids (PUFA) – it comprises 80% unsaturated fatty acids, with 50% being monounsaturated and 30% being

What are the common extraction methods of extracting peanut

- Type: peanut oil processing machine

- Production capacity: 98%

- Voltage: 380 V/50 HZ

- Weight : depends on the capacity of the palm oil production line

- Dimension (L*W*H) : depends on the machine equipment

- Power (W): depends on the machine equipment

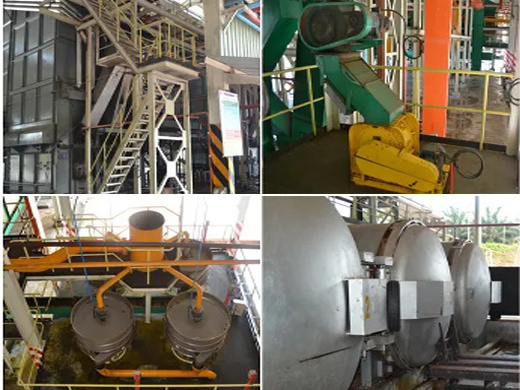

Recommended reading: Peanut oil processing plant. Peanut oil pretreatment and pressing machine. Although the peanut pretreatment machine is necessary, the peanut oil press machine is also important. As the core equipment of the peanut oil pressing production line, peanut oil press machine plays a huge role in the whole peanut oil pressing process.

Above is the main peanut oil extraction methods that are widely used in commercial vegetable oil processing plant to improve the oil production efficiency and oil quality. Before starting the peanut oil extraction process, the peanut/groundnut should be pretreated to ensure high oil output.

(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Usage: peanut oil

- Production capacity: 50-70 kg

- Voltage: 220 V

- Main components: motor, pressure vessel, bearing, Motor, gearbox, oil press

- Weight: 280 kg, 280 kg

- Dimension (length x width x height): 1400x950x1250 mm

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

We offer you complete peanut oil production solutions. No matter small peanut oil plants from 1 TPD to 50 TPD, or large-scale peanut oil plants up to 5,000 TPD, we will work with you to make the best solution. Our peanut oil production line is a comprehensive, multi-stage setup designed to extract and refine oil from peanuts.

Groundnut Oil Making Process (Peanut), Business Plan

- Type: cooking oil extraction machine

- Production capacity: 10-5000 tons

- Power (W ): Depending on the oil ejectors daily production

- Voltage: 380 V 440 V

- Dimension (L*W*H): Depends on the capacity of the oil ejectors

- Weight: According to the production of the ejectors of seed oil for cooking

Peanut oil pressing methods. Divided by pressing temperature, there are two types of peanut oil pressing methods they are hot pressing technology and cold pressing technology. Hot pressing method is the traditional process of peanut oil. Peanut oil is steamed fried and pressed, generally at a temperature above 120 ℃ with a high rate of oil

Peanuts contain around 24% to 36% crude protein on a dry weight basis, which is second only to soybean (36% to 51%) in edible oil crops [3].Peanuts contain 8 essential amino acids and are rich in unsaturated fatty acids and linolenic acid, as well as various other health-promoting components, such as vitamins, procyanidins, flavonoids, and resveratrol [[4], [5], [6]].

peanut oil extraction machine - Hongde Oil Machinery

- Raw Material: peanut

- Production capacity: 100% refined sunflower oil edible machine

- Power (W): 5.5-22 KW

- Voltage: 220V/380V/440V

- Dimension (L*W) *H): 48m*12M*15M(30TPD)

- Weight: 30 tons

Adopts the most advanced peanut/groundnut oil extraction technology to ensure high efficiency, economical and reliable crude peanut/groundnut oil extraction process. . Cooperated with vacuum evaporation oil extraction design, solvent condensation and tail gas recovery system, the oil extractor can obtain crude peanut/groundnut oil with high oil yield, low residual oil, low solvent consumption

A study carried out in 2019 by Suri et al. examined how peanut oil quality characteristics were affected by a combination of dry air roasting and mechanical extraction using screw pressing . The researchers found that optimal conditions for air roasting were 180 °C for 10 min, followed by cooling at room temperature.