Peanut Oil Processing Technology - ScienceDirect

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: 10 TONS /DAY

- Voltage: 30 hp

- Warranty: 1 year

- Weight: 1000 KG

- Dimension (L*W*H): 2261MM*686MM*1423MM

- Country: zambia

Only less than 10% of peanut oil is produced with cold pressing technique, but the peanut oil produced with this technique maintains the original nutritional quality of peanuts, and peanut protein powder with low variability can be produced during the pressing process so that both the peanut utilization rate and the economic benefits can be

Peanut Oil Manufacturing Plant Report: Setup & Cost - IMARC Group

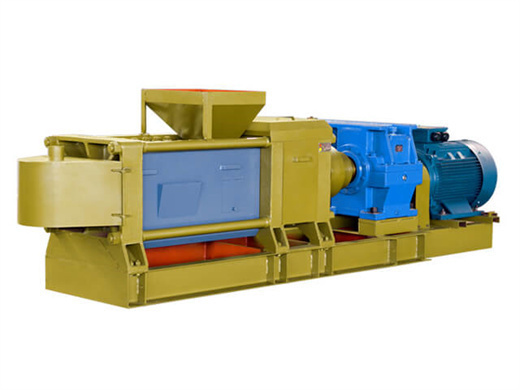

- Type: peanut oil processing machine

- Production capacity: 100TPD castor oil plant

- Voltage: 220V/380V/440V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on capacity

IMARC Group’s report, titled “Peanut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a peanut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit

peanuts further and causes them to turn brown as peanut oil stains the peanut cell walls. Following roasting, peanuts are prepared for packaging or for further processing into candies or peanut butter. Typical peanut roasting processes are shown in Figure 9.10-2.2-3. There are 2 primary methods for roasting peanuts, dry roasting and oil roasting.

(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Usage: peanut oil

- Product type: Wood oil

- Processing type: Cold pressed

- Volume (L): 1 liter

- Purity (%): 99 %

- Packaging: Drum

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

Production, Processing, and Food Uses of Peanut Oilseed, Oil

- Type: cooking oil extraction machine

- Production capacity: 20-5000T/D

- Power (W) : up to specification

- Voltage:380v

- Dimension (L*W*H): 1360*950*1170 mm

- Weight: as per specification

In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

The main peanut processing is crushing for oil, contributing to approximately two-thirds of the world's peanut production, while the remaining is used in food preparations [6, 7]. Peanut kernel is

Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Raw Material: peanut

- Production capacity: 10-5000 tons

- Power (W ): As cooking oil refining equipment daily production

- Voltage: 380 V 440 V

- Dimension (L*W*H): Depends on the capacity of cooking oil refining equipment

- Weight: According the output

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant

Peanut (groundnut, earth nut) oil production worldwide was about 5.4 million metric tons and has remained fairly static over the past decade. In 2014, 291,000 metric tons were crushed for oil (12%