Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Usage/Application: cottonseed

- Production capacity: 1-500T/D

- Voltage:220V/380V

- Weight:30 tons

- Dimension (L*W*H )):46*32*12m

- Power ( W): 10-50kw

- Country: botswana

Learn about these points before you start your own cotton seed oil mill plant: Conduct thorough research on the what you require for cottonseed oil business in terms of market size, capital and trends. Know your competitors. Make a business plan and write down your planned location, finances and target market. Learn about the rules and regulations.

rnew type cottonseed oil expeller in zimbabwe

- Type: cottonseed oil processing machine

- Production capacity: 50-500 kg/h

- Voltage: 180 w

- Main components: Motor

- Weight: 100 kg

- Dimension (L*W*H): 460x225x260 mm

Cottonseed oil extraction involves a series of oil manufacturing process and professional oil processing machinery. Whatever your cottonseed oil mill plant is small or large, the basic manufacturing process is needed to produce high quality cottonseed oil.

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption.

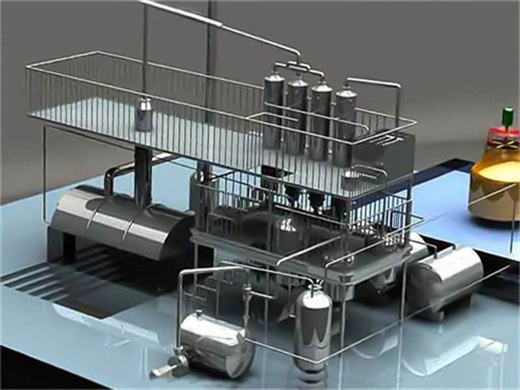

Cottonseed Oil Manufacturing Process and Machinery

- Usage: cottonseed oil

- Production capacity: 10TPD

- Voltage: 380V

- Function: Hydraulic cold avocado oil press

- Weight : 1500KG

- Dimension (L*W*H): 1300*1200 *2350mm

Then, the crude cottonseed oil is made and the cottonseed oil cake is discharged for next processing for feed or other usages. Oil Refining: Since the crude cottonseed oil contains high content of gossypol, it needed to be refined to improve the quality and ensure the final refined cottonseed oil is completely safe for eating.

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Factory Price Cotton Seed Oil Mill Machine for Sales | ABC

- Type: cooking oil extraction machine

- Production capacity: 1-800TPD

- Power (W): 18 .5 KW

- Voltage: 220/380V

- Dimension (L*W*H): 430*230*350

- Weight: 1050 KG

The cottonseed oil machine designed by Our Machinery is Screw Oil Press Machine that is now the most popular cooking oil processing machine in market since it can process various plant seeds or oilseeds such cottonseeds, sunflower seeds, peanut/groundnut, soybeans, palm kernel, sesame seeds, flaxseed, almond, moringa, coconut/copra, and more.

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

new type cottonseed refined rapeseed oil processing plant

- Raw Material: cottonseed oil

- Production capacity: 50 kg per hour

- Dimension (L*W*H): 840*240*540 mm

- Voltage: 220-240 volts

- Weight: 65 KG

- Guarantee: 2 years

innovations in extraction: the future of cottonseed oil. dive into the health benefits of cottonseed oil, the intricate steps of its extraction process, and the essential machinery for a 150-ton-per-day plant. gain insights on large-scale design, environmental sustainability, economic viability, and operational strategies.

By automatically controlling the temperature, the actual oil yield can be increased by 10-30%. Made of stainless steel, the cotton seed oil making machine is clean, durable, and easy to clean. Vacuum filtration, fewer impurities, and good oil quality. The cotton seed oil press can be equipped with two vacuum oil filter barrels for filtration.