cooking oil refining plant in lagos - Complete Oil

- Type: peanut oil refinery equipment

- Usage/Application: peanut, groundnut

- Production capacity: 1-200T/D

- Voltage: 440V/380v

- Weight: custom made

- Dimension (L*W*H): custom made

- Power (W) : custom made

- Country: lagos

2tpd groundnut oil pressing line is very suitable for small scale groundnut oil mill. Except for the automatic temperature controlled integrated oil press machine with vacuum filter, the 2tpd small scale groundnut oil pressing line also includes two sets of screw conveyor, a set of drum roaster and PLC control system.

Small Edible Oil Refinery Plant

- Type: peanut oil refinery machine

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Weight: According to the order of the oil extraction plant

- Dimension (L*W) *H): According to the order of the oil extraction plant

- Power ( W): Capacity

So ,that’s the purpose of oil refining. Preparation Before Crude Oil Refining. The operation conditions are different according to different kinds of crude oil, the following operating instructions are only for reference. Crude Oil Test: Determine the acid value and color. If conditions permitting, do a small sample experiment in the laboratory.

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.

Oils Fats Refining Equipment and Turnkey Plants - Myande Group

- Usage: peanut oil

- Production capacity: ≥98%

- Voltage: 380 V

- Main components: motor, gear, gearbox, frame, juicer part, feeding system

- Weight: 980 KG

- Dimension (length x width x height): 2200*750*1700 mm

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

The batch-type oil refining equipment is commonly used in small oil press plants. It performs several refining processes in a batch mode, allowing for control over the refining process, and flexibility for refining almost all the crude oil. The capacity is from 1t/d to 20t/d.

Small Scale Edible Oil Refinery Equipment for Oil Mill Plant

- Type: cooking oil refining machine

- Production capacity: 1-500T/D

- Voltage: 380V-415V

- Weight: depends on palm oil machine mode the palm oil machine

- Dimension (L*W*H): depends on palm oil machine mode

- Power (W) : depends on palm oil machine mode

Please note: for self-employed entrepreneur and small-business owner, 1-10 tons/day batch type oil refinery production line is their best choice to refine crude oil into the first or second grade edible oil(e.g. peanut oil, rapeseed oil, tea seed oil, soybean oil, sunflower oil, etc.) with features of multi-purpose, easy transportation, small

Peanut oil refined is also the most important part of the peanut oil production process. After refining, the peanut oil color is bright and clean. Not only free of impurities in crude oil, but also has high practical value and is easy to preserve. More importantly, nutrients such as vitamin E in peanut oil are retained.

Batch Type Small Edible Oil Refining Plant - Oil mill

- Raw Material: peanut

- Production capacity: 100 kg/hour-10000 kg/hour

- Dimension (length x width x height): 53*27* 35cm

- Voltage: 220 V

- Weight: 14kg

- Key Selling Points: Energy Saving

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

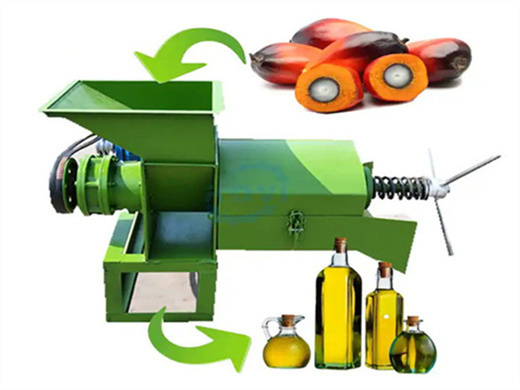

Oil Pressing process: After preprocessing, the soybean and peanut are ready for oil expelling. Filtering oil: Filtering the crude oil with oil-dreg sieves, which run reposefully, less malfunction, less occupying area, it’s the better oil-dreg separator, then use oil filter. Edible Oil Refining Process