setting up a peanut oil refinery plant in malawi

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: 10-100TPH

- Voltage: 220V/380V/440V

- Weight: According to cooking oil processing capacity

- Dimension (L*W) *H): 1200*400*900mm3

- Power (W) : 10-50kw

- Country: malawi

Adopts the most advanced peanut/groundnut oil extraction technology to ensure high efficiency, economical and reliable crude peanut/groundnut oil extraction process. Cooperated with vacuum evaporation oil extraction design, solvent condensation and tail gas recovery system, the oil extractor can obtain crude peanut/groundnut oil with high oil yield, low residual oil, low solvent consumption, and low equipment failure.

Set up Your Own Small Oil Pressing Production Line at Lowest Cost

- Type: peanut oil processing machine

- Production capacity: 30-300TPD

- Voltage: 380 V / Three Phase

- Weight: According to its capacity

- Dimension (L*W*H) : 1200*400*900mm3

- Power (W ): According to its capacity

The conditions of starting a small scale oil pressing line is relatively simple and easy, especially for novice in oil processing industry. 5TPD Mini Cooking Oil Production Line. The small oil pressing line we designed and built can process cotton seeds, palm kernels, coconut, peanut, almond, prickly pear seeds, rapeseeds, mustard seeds

This gives you insights into everything you will need to establish and run a business successfully. Step 3. Select your source of raw materials. You have two options to obtain the raw materials needed for the vegetable oil extraction plant. You can buy oil seeds from the supplier or have your own farm for the cultivation of oil seeds & nuts

edible oil pressing machines costs in malawi | Strong

- Usage: peanut oil

- Production capacity: 80-600 kg/h

- Voltage: 220V 380V or local voltage

- Weight: About 2000kg

- Dimension (L*W* H): 2500*1600*2500, depending on model

- Power (W): Energy saving

To meet the international industry’s standards for edible oil, the crude palm oil produced by oil mills should be refined in palm oil refinery plan t. Palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

IMARC Group’s report, titled “Peanut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a peanut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit

How to Start Your Own Groundnut,Peanut Oil Production Business?

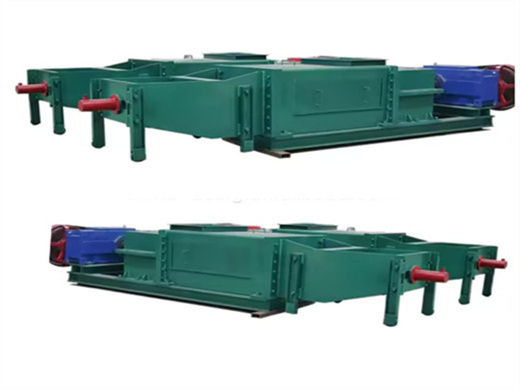

- Type: cooking oil extraction machine

- Production capacity: 45 sets per year

- Power (W): 30KW

- Voltage: 380V/440V

- Dimension (L*W*H): 1200*2800*1200mm

- Weight: 500TON

In this time, the chemical method solvent extraction will be a good way to fully extract peanut oils. The solvent extraction method can make the residual oil rate of the groundnut meal below 1%. So for edible use, the pressed crude groundnut oil needs to be refined by filter presses or oil refining plant. Groundnut Oil Extraction Plant

That place should not be too far away from the place where you would procure your raw materials. The target market should not be far away too as you might incur transportation costs. 4. Personnel: You require people to run your small cooking oil processing plant. You should have a pool of employees from whom you can make a correct choice.

How to Start Groundnut Oil Mill Plant | OM Engineering Works

- Raw Material: peanut

- Production capacity: 1-16 tons per day

- Dimension (L*W*H): 1.8 m*1. 5 m *1.9 m

- Voltage: 380 V

- Weight: 1400 KG

- Main components: motor, pressure vessel, pump, gear, bearing, motor, gearbox

The cost of setting up a groundnut oil extraction plant depends on various factors such as the capacity of the plant, the processing method used, the equipment required, and the scale of the

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant