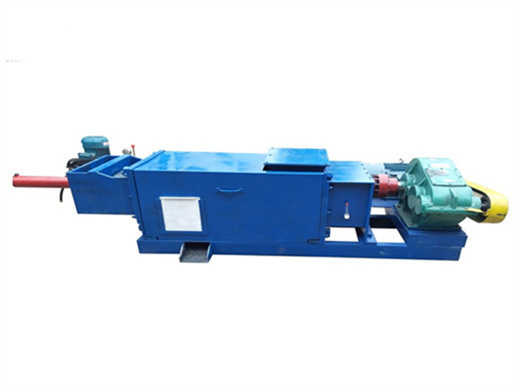

SAND TRAP TANK (Equitment Clarification Stasion) ~ Palm Oil

- Type: soybean oil plant

- Usage/Application: soybean

- Production capacity: 100kg/h-1000kg/h

- Voltage: 220V/110V

- Cap: European plug, Plug American, etc

- Raw material: coconut, sesame, peanuts, olive, soybeans, rapeseed, etc.

- Dimension (length x width x height): 38 x 22 x 29 cm Weight: 5 kg Main components: Pump

- Country: south africa

Proses Kerja Crude oil hasil dari pengepresan dialirkan melalui oil gutter (talang minyak) dan masuk kedalam sand trap tank, material yang mempunyai berat jenis lebih berat (pasir) akan mengendap dan harus dilaksanakan drain secara kontiniu pada setiap pergantian shift. Selanjutnya material dengan berat jenis yang

Analysis of Sludge Separator Using Failure Mode Effect

- Type: soybean oil processing machine

- Production capacity: 1 tpd

- Voltage: AC220V, AC220V

- Main components: Motor, cooking oil processing machine

- Weight: 9.2KG

- Dimension (L*W*H): 420mm*180mm*280mm

1 Sand Trap Tank serves to trap sand and dirt contained in oil 2 Vibrating Screen serves as a filter of dirt or solid objects (sand, shell, nut) and consists of several filtration rates of 30 and 40 mesh 3 Crude Oil Tank serves as a reservoir of oil that has been filtered by vibrating screen before transferred to CST 4 Balance Tank

Oil tank merupakan tangki minyak dengan tipe silinder yang berfungsi untuk menampung minyak yang berasal dari over flow tangki pemisah minyak (CST). Fungsi dari oil tank adalah untuk pengendapan kotoran dan air yang terikut dari CST, minyak tersebut selanjutnya akan dipompakan menuju ke Oil Purifier maupun langsung masuk (bypass) ke Vacumm Dryer.

THE OIL PALM PLANTERS: TEKNOLOGI KLARIFIKASI MINYAK SAWIT

- Usage: soybean oil

- Production capacity: 5t/h

- Voltage: 220V380V

- Main components: motor, pressure vessel, PLC

- Weight: 300 KG

- Dimension (L*W*H): 1.2*0.78*1.1m

Cairan yang keluar dari alat press dan digester ditampung dalam “Oil Gutter” dan dialirkan kedalam Sand Trap Tank. Alat ini berfungsi untuk mengurangi jumlah pasir dalam minyak yang akan dialirkan keVibrating Screen (ayakan getar), dengan maksud agar ayakan getar terhindar dari gesekan pasir kasar yang dapat menyebabkan kehausan ayakan

- A two-basin sand trap located upstream of the impoundment. Sized to eliminate grains of more than 0.2 mm, it will effectively be 55 m long. The discharge valve will be in a dedicated concrete structure located downstream of the energy dissipation basin, making it possible to transport the sand on the river bed directly

Sand Trapping Tank Plantsoybean Oil in ethiopia

- Type: cooking oil extraction machine

- After-sales Service: 24 Hours Online Service

- Press Series: Fourth

- Structure: Vertical

- Voltage: 380V/220V

- Model: 50A/70A/85/100

The total combined Prospective Resources for the 3 blocks are estimated to contain 954 million barrels of oil (unrisked, Best Estimates, 100% basis) with 143 million net to FAR. An immediate follow up well is planned in 2014 in the event of success on the West Sinapa well.

Sand trap tank berfungsi menangkap pasir dalam minyak sebelum dialirkan ke vibrating screen untuk mencegah kerusakan. Vibrating screen memisahkan padatan dari minyak dengan getaran pada berbagai ukuran mesh. Crude oil tank menampung minyak dari vibrating screen sebelum dipompa ke tangki pengendapan minyak untuk mengendapkan partikel besar.

Introduction to Crude Palm Oil (CPO) Dilution - Blogger

- Raw Material: soybean

- Production capacity: 20 tons/day

- Weight : 4000 KG

- Dimension (length*width*height): 11.48*4.26*11.81 feet

- Main components warranty: Others

- Main components: Others

Good dilution will produce lower oil loss at clarifier tank underflow and effective separation within oil water and solids, it can be verified at sand trap tank, we will be able to see oil sells size of 50 cent coin floating and merge with bigger oil cells. Table below shows some comparison within good and poor dilution by physical view.

Crude oil yang sudah dikurangi material beratnya oleh Sand Trap Tank dimasukkan ke bagian atas vibrating screen, crude oil hasil penapisan akan dialirkan ke dalam Crude Oil Tank, sedangkan padatan/solid yang masih banyak mengandung minyak dikembalikan ke Fruit Elevator melalui Waste Conveyor untuk daur ulang.