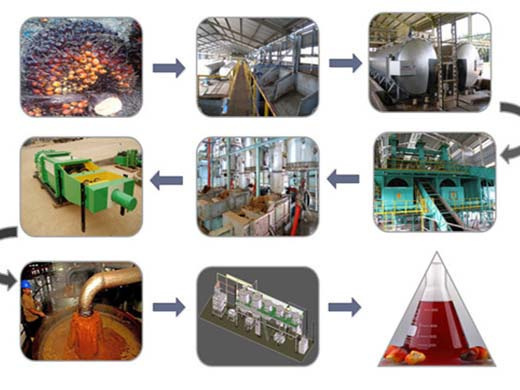

Palm Oil Production Process: A Step-by-Step Guide

- Type: palm oil processing plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 180-250 kg per hour

- Voltage: 380 V

- Main components: Others

- Weight: 1280 KG

- Dimension (L*W*H): 2100*1400*1700 mm

- Country: johannesburg

Our Machinery is a leading manufacturer specializing in palm oil milling equipment. With a wealth of experience and cutting-edge technology, we deliver high-quality machinery for efficient palm oil production. Our advanced equipment ensures optimal extraction, refining, and processing of palm oil, maximizing yield while maintaining superior

Process flow diagram for palm oil production

- Type: palm oil processing machine

- Production capacity: 1t/day-1t/hour---100%

- Voltage: 380V

- Main components: motor, pressure vessel, pump, gear, bearing, motor, gearbox

- Weight: 1200 KG

- Dimension (L*W*H)): 2300 *1630*1600mm

Finally, we use double screw palm oil presser to get crude palm oil, which improved the production efficiency greatly. After this step, the palm oil production process is not over. The crude oil need to be further treated to purify and dry it for storage and export. Palm oil processing plant production list:

Offer turnkey palm oil press plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing Our palm fruit oil processing plant capacity range from 3t h to 100t h with automatic palm oil mill control system

3. PALM OIL PROCESSING

- Usage: palm oil

- Customized: Not customized

- Capacity: 350-500kg/H

- Certificate: Ce

- Weight: 1500 kg

- Power: 18. 5 kw

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

In addition to medium and large palm oil extraction plant, we can also customize different daily processing capacity of small scale palm oil production lines for small business, such as: 1 ton/hour, 2 tons/hour, 3 tons/hour, 5 tons/hour, etc. Small scale palm oil extraction plant include six steps: threshing, sterilization, digestion, pressing, crude oil clarification and filtration, all of

Palm Oil Mill FFB Oil Extraction into CPO (Crude Palm Oil)

- Type: cooking oil extraction machine

- Press Materials: Rice

- Custom: Custom

- Press Series: Second

- Certificate: CE, ISO

- Method: Chemical refining, Physical refining

Complete FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Threshing & Extraction Processing & Refining & Fractionation Machinery and Solution with Full Around Technology and Service! Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 100 MT per hour of FFB.

The kernels are further processed in palm kernel oil extraction plant to produce palm kernel oil (PKO) and palm kernel cake (PKC). The rate of FFA increase is much faster in broken kernels. So try to keep the kernel breakage as low as possible during the nut crushing processes. Palm Oil Extraction Manufacturer & Supplier

automatic palm kernels oil extractor machine in johannesburg

- Raw Material: palm

- Power (W): 39kw

- Dimension (L*W*H): 1500*900*1900mm

- Weight: 200kg

- Material: 304 stainless steel

- Control system: automatic

QIE Machinery and equipment are known for their superior quality and stand the test of time. Each piece of equipment undergoes stringent quality control to ensure its stable and efficient operation. We have successfully implemented numerous crude palm oil plant projects not only in africa but also around the world. We understand the market needs and challenges in different regions and provide customized solutions to our customers.

Palm kernel oil is an important component of African cuisine and rural industry. The traditional method of oil extraction currently utilized in rural areas is arduous, time consuming and inefficient. To mechanize the oil extraction process, a screw press implement for the multi-function platform diesel engine was designed.