Semi-automatic hot peanut oil filling machine

- Type: peanut oil filling machine

- Usage/Application: peanut, groundnut

- Production capacity:95-100%

- Voltage: 380 V

- Oil type: Flax seed oil, Rap seed oil, Tea seed oil, Basil oil, SESAME OIL, Pine nut oil, Sunflower seed oil, Walnut, OLIVE OIL, Oil

- Main components: motor, container pressure, pump, motor, tank, filter, Meter box

- Weight: 3280 KG

- Country: johannesburg

Semi-Automatic Peanut Butter Filling Machine, High Quality Semi-Automatic Peanut Butter Filling Machine. Power: 10W Filling Speed: 0-10bottles/min Filling Accuracy: ±1% GT series peanut butter filling machine, also known as semi-automatic piston filling machine, is a reliable and efficient solution for accurate filling of high viscosity liquids and pastes.

Oil Filling Machine Supplier - Oil Fillers - Filling Equipment

- Type: peanut oil processing machine

- Production capacity: residual press cake: ≤ 6%

- Voltage: 220V/110V

- Main components: Motor

- Weight: 100kg

- Dimension (L*W*H): 41*16* 31cm

We provide automatic and semi-automatic oil filling machines. Visit our website or give us a call to discuss how we can help you with all your filling machine needs. Call us Now 718-445-2111

2. The semi-automatic oil filling machine is quantitative cup structure, driven by the oil-cylinder piston’s repeated movement which driven by air-cylinder, quantitative filling the oil into bottles, high accuracy, speed filling, double speed filling, slow down after fast, more accurately . 3.

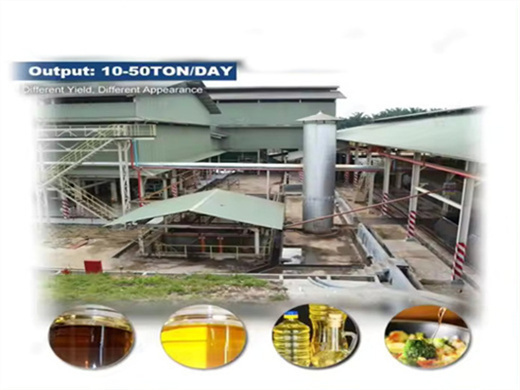

Semi Automatic Filling Machine - Automatic Bucket Filling

- Usage: peanut oil

- Production capacity: 10-50 tpd domestic oil press

- Voltage: 220V/380V/ 440V

- Weight: 0.5-10T

- Dimension (L *W*H): 1700*1300*1600

- Power (W): 15kw

The Automatic Weight-Based 6-Head Oil Tin Filling Machine is a high-performance solution designed for precise and efficient filling of oil products into tins. This machine is ideal for large-scale production in industries like edible oils, lubricants, and chemicals.

Since there are many types of edible oil, Sunter Machinery provides linear type oil filling machine and rotary type oil filling equipment for customers to choose from. The main material of the edible oil bottling machine is SS304 stainless steel, which meets the sanitary requirements.

Experienced supplier of lubricant filling machine,lube oil

- Type: cooking oil extraction machine

- Production capacity: 100kg/h, 500kg/h, 1tph, 5tph, 10tph

- Power (W): Capacity

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 850 KG

A lubricant oil filling machine is a specialized piece of equipment designed for the efficient and accurate filling of lubricating oils. These machines are sometimes referred to as lubricant filling lines and are used in the lubricant industry to fill containers of different sizes and shapes with a range of lubricant oils, including engine oil, motor oil, and other specialized lubricants.

Advantages of Using Lube Oil Filling Machines. Lube oil filling machines offer several key advantages that make them indispensable in industrial settings. Efficiency and Accuracy: These machines are designed for high-speed operation, drastically increasing productivity. Moreover, their precision in filling ensures consistent product quality

Oil filling machine, Oil filler - All industrial manufacturers

- Raw Material: peanut

- power input: 28KVA

- temperature: 0~200C ( adjustable)

- power output: 20KW

- magnetron: Panasonic

- conveyor belt: Teflon

CB OIL is a semi-automatic oil bottling machine with innovative features that make it suitable for filling bottles and cans from 200g - 10 kg. Compare this product Remove from comparison tool automatic filling machine HEMA ACCES

peanut production line has several advantages: high oil yield, high degree of automation, energy saving and environmental protection, and customized services. Hongde Machinery provides comprehensive customized services, tailoring complete pre-pressing and extraction production lines according to the specific needs of customers (such as raw material characteristics, production scale, product standards, etc.).