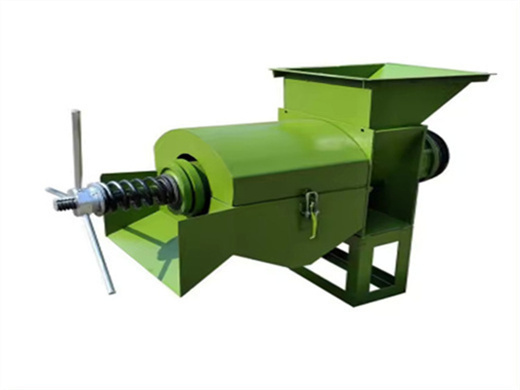

Kumar’s Palm Kernel (PK) Series Oil Expeller Machine

- Type: palm kernel oil expeller

- Usage/Application: palm fruit, palm kernel

- Production capacity: 50 kg/h

- Voltage: 380 V

- Main components: screw

- Weight: 180 KG

- Dimension (L*W*H): 1000*538*1050 mm

- Country: johannesburg

Specially designed and manufactured for maximum oil extraction from palm kernel. Minimal residual oil content in the second press cake. Independent gearbox system reduces noise level, consume less power and ensure zero contamination of mineral oil with edible oil. Alloy steel with ultrasonically tested screw shaft with heavy-duty branded bearings.

Palm Kernel Oil Mill Manufacturer & Exporter - GOYUM SCREW PRESS

- Type: palm oil processing machine

- Production capacity: 10-1000T/D

- Voltage: 380V, 220V

- Weight: 1000kg

- Dimension (L*W*H): 900*850*1550(mm)

- Power (W): 11 KW

As an expert in manufacturing palm kernel oil mill machinery and full scale production plants, GOYUM-INDIA is your reliable choice for starting an oil extraction business. We can offer Small scale to large Industrial scale Palm Kernel Oil Production Plant ranging from 15 TPD to 500 TPD.

Sunflower Oil Press Machine Equipment Manufacturers. LYZX28,32 low-temperature screw expeller is applicable for the low-temperature production of vegetable oil, oil-bearing crops such as rapeseed, husked rapeseed kernel, peanut kernel, chinaberry seed, tea seed kernel, sunflower seed kernel, cotton seed kernel, etc. can be pressed.

Palm Kernel Expeller (PKE): A Versatile By-Product Driving

- Usage: palm oil

- Production capacity: 5TPH-80TPH

- Voltage: 380V/50Hz

- Weight: 2 TONS

- Dimension (L*W*H): 1.5*2.6*3.6M

- Power (W) : 22kw

Palm Kernel Expeller (PKE) is a vital by-product derived from the palm oil extraction process, renowned for its rich nutritional composition and multifaceted industrial applications. This article delves into the production methods, nutritional benefits, diverse industrial uses, sustainability considerations, and global significance of Palm Kernel Expeller, highlighting its pivotal role in

In most situations, unless it’s a specialised oil-bearing material like palm kernel, we would recommend going for a multi-purpose oil expeller. Durability; It is far from easy to assess the durability of an oil expeller and to know if the price of oil expeller machine is justified by its design and engineering.

MBL’s History and Milestones in the Palm Kernel Expeller

- Type: cooking oil extraction machine

- Production capacity: 3kg/h

- Dimension (L*W*H): 430x50x350mm

- Oil Type: Cooking Oil

- Main components : Gear, Bearing

- Weight: 3 KG

Muar Ban Lee Group (MBL) started its journey in the palm kernel expeller machines industry in 1987. We were a small team with big dreams, and we stood out by constantly improving our machines through research and development. Over time, we expanded into palm oil machinery and oil seed crushing machinery.

Copra Oil Expellers,Copra Machines,Copra Machines Crushing Plant. The moisture content in the kernel should not be more than 7%, based on M.E.O.M.A. Standard. After 1st pressing. 12% to 14% oil content remain in cake. After 2nd pressing. Less than 7% oil content remain in cake. Worm & Collar / Worm Screw.

malaysia oil expeller wholesale in johannesburg

- Raw Material: palm

- Product extraction system: roasting system

- Packaging detail: 20ft, 40ft container

- residual oil content: maximum 1%

- solvent raw material: rice bran, canola, seed sunflower, peanut, soybean, groundnut, etc.

- Capacoty: according to your requirements

Malaysia Palm Kernel Expeller | Mills Manufacturer - MBL. Muar Ban Lee Group is a world-leading palm kernel expeller manufacturer specializing in palm oil machinery and oil seed crushing machinery. We provide "One Stop Service" in setting up Palm Kernel Crushing Plants from Plant Design and Fabrication to Installation and Commissionning.

Bulk Palm Kernels Shipping. Palm Kernels: When crushed the fruits (kernels) of various varieties of palm trees provide palm oil (or fat) used to make soaps, candles, etc. . This crushing process may take place where the plants are grown and the resulting oils shipped in specialised parcel tankers leaving the remaining expellers to be transported in bulk in dry bulk carr