Cottonseed Oil Processing Plant | Extraction Flow

- Type: cottonseed oil extraction machine

- Usage/Application: cottonseed

- Model NO.

- SRP239

- Press Series

- Oil Crops

- Press Materials

- Country: zimbabwe

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

Effect of different extraction methods on cottonseed oil yield

- Type: cottonseed oil processing machine

- Production capacity: 1t/day-1t/hour-100%

- Voltage: 220V/380V

- Main components: motor, pressure vessel, PLC

- Weight: 820 KG

- Dimension (L*W*H)): 2050 *980*1700mm

The aim of the present study was to compare different extraction methods (Soxhlet, mechanical and ultrasound-assisted) in order to achieve the highest extraction yield of cottonseed oil (CSO). The

Muhammad Bilal (2021): Cottonseed oil: A review of extraction techniques, physicochemical, functional, and nutritional properties, Critical Reviews in Food Science and Nutrition, DOI: 10.1080

What is the manufacturing process of cottonseed oil?

- Usage: cottonseed oil

- Production capacity: 450-600 kg/h

- Place of Voltage: 380v, 6 levels,

- Certification: CE, ISQ, BV

- Dimension (L*W*H): 2500*1600*2500

- Power (W): 18.5 KW

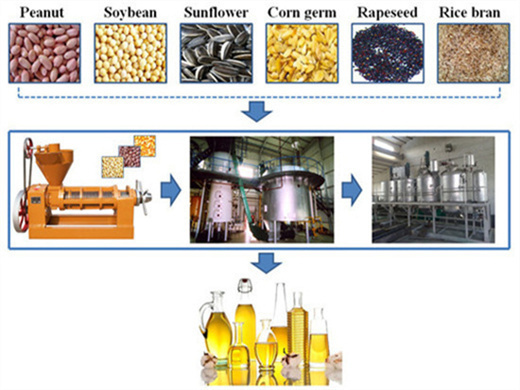

Cottonseed oil extraction involves a series of oil manufacturing process and professional oil processing machinery. Whatever your cottonseed oil mill plant is small or large, the basic manufacturing process is needed to produce high quality cottonseed oil. The detailed cottonseed oil manufacturing processes is as follows. Cleaning: Getting rid of organic impurity (stems and leaves, […]

Cottonseed Oil Extraction Process. Our cottonseed oil extraction plant uses a well-structured process to extract premium oil from cotton seeds. With precise cleaning, dehulling, and solvent extraction, we ensure maximum yield and purity for various industrial and edible applications.

Complete cotton seed oil processing plant_Blog

- Type: cooking oil extraction machine

- Production capacity:10TPD

- Voltage:380V

- Material: Stainless steel

- Oil type:Flax seed OIL SESAME, sunflower seed oil and walnut

- Main components:Others, gears

This method has a relatively low residual oil rate and is widely used in oil extraction. The cotton seed oil processing plant using solvent extraction technology to make cottonseed oil also need pretreat the cottonseeds with some machines. The cleaning and pre-pressing machines are same as those used in pressing line.

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Cotton Seed Processing, Oil Extraction & Refining Plant

- Raw Material: cottonseed oil

- Production capacity: High efficiency

- Dimension (L*W*H): 450*180*310MM

- Voltage: 110V/220V

- Weight: 11KG

- Key Selling Points: Automatic

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

(DOI: 10.1080/10408398.2021.1963206) Seed oils are the richest source of vitamin-E-active compounds, which contribute significantly to antioxidant activities. Cottonseed oil (CS-O) is attaining more consideration owing to its high fiber content and stability against auto-oxidation. CS-O has gained a good reputation in the global edible oil market due to its distinctive fatty acid profile, anti