Palm Kernel Oil Expelling Machine Palm Oil Making Machine

- Type: palm kernel oil press machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 60-400 kg/h

- Voltage: Customizable

- Main components: Motor

- Weight: 1100 KG

- Dimension (L*W*H): 1800*1200*1550 mm

- Country: botswana

Fresh palm fruit is shipped from the field in bunches or loose fruit. Fresh palm fruit is usually poured into suitable wooden boxes so that the quantity of fruit arriving at the processing site can be checked. Large installations use weighbridges to weigh materials in trucks.

Palm Oil Machine - Palm Oil Production Line

- Type: palm oil processing machine

- Dimension (L*W*H): 1420x850x2600mm

- Production capacity (kg/h): 500 - 600

- Main components: Motor

- Power (kW): 3kw

- Outgoing inspection video: Provided Product size sieve (mm): 280x650mm

Huatai Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press, palm kernel oil extraction machine, CPO Refinery, and palm oil fractionation plant. Our team offer turnkey production solution for complete palm oil processing project with competitive cost!

In this column, we will provide comprehensive insights covering everything you need to know about building a palm oil processing plant in Indonesia. Maybe the feasibility, cost analysis, profitability, site selection, layout design, processing machine purchase, local regulations, and more. No jargon, just the essential info you need.

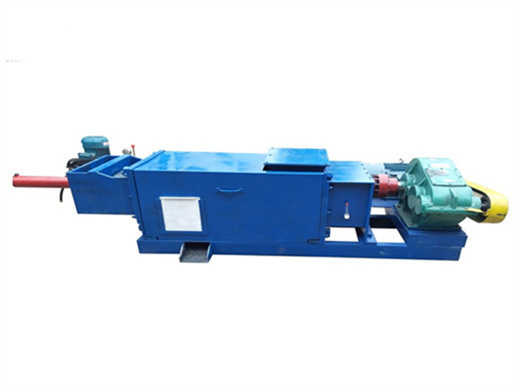

Palm Kernel Oil Expeller for Cold Pressing of Palm Kernel Oil

- Usage: palm oil

- Production capacity: 8~10TPD

- Voltage: 220V/380V

- Main components warranty: 3 years

- Weight: 960kg

- Dimension (L*W*H): 2100*820* 1400

Palm Kernel Oil Press Machine Applications. Our palm kernel oil press is suitable for pressing high-oil-content oilseeds such as shelled peanuts, tea seed kernels, sunflower kernels, cottonseed kernels, rapeseed kernels, walnuts, rubber seeds and peeled soybeans at room temperature or at low temperature.

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Huatai palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

palm oil line

- Type: cooking oil extraction machine

- Production capacity: 150-250Kg/h

- Dimension (L*W*H): 1900*1400*1700mm

- Oil type: cooking oil

- Core Components: motor, pressure vessel, pump, gear, bearing, motor, gearbox

- Weight: 1100 KG

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

Palm kernel oil is an edible plant oil extracted from the palm kernel, a by-product of the palm oil mill plant. Our Palm Kernel Oil Press Machine is designed to meet the needs of modern palm kernel oil production with capacities ranging from 10 TPD to 100 TPD. Engineered with precision and innovation, it delivers high-quality oil extraction

PALM KERNEL OIL PRESSING MACHINE

- Raw Material: palm

- Production capacity: 98%-100%

- Power (W): 5.5 KW~15KW

- Voltage: 380

- Dimension (L*W*H): 2200*1600*2150

- Weight: 780kg

Palm Kernel Oil Pressing Plant Flow Chart: Main process in palm kernel press line: Palm kernel Cleaning : It is used for removing the iron impurities, stone, fiber and pthers. These impurities are bad for machines, especial for the palm kernel oil expeller. Palm kernel crushing:because the palm kernel is hard and big size, it is required to

Palm kernel oil press machine, also known as palm kernel oil expeller. This machine is suitable for peanut, palm kernel, sesame, palm, soybean, sunflower, rapeseed, olive etc. It is high efficiency with mature product structure and process, the oil yield can be comparable to the large oil press.