Palm Oil Machine - Palm Oil Production Line

- Type: palm oil production line machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: according to capacity

- Voltage: 220v,380v,440v

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260 mm

- Power (W): according to capacity

- Country: malawi

High quality high oil yield and design of Palm Oil Production Line is the key to success of palm oil plant business. Hongde Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press, palm kernel oil extraction machine, CPO Refinery, and palm oil fractionation plant. Our

Palm oil production line | Palm oil mill - Hongde Oil Machinery

- Type: palm oil processing machine

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V

- Weight: According to your capacity

- Dimension (L*W*H): According to your capacity

- Power (W) : Capacity

Palm oil production line. Hongde Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

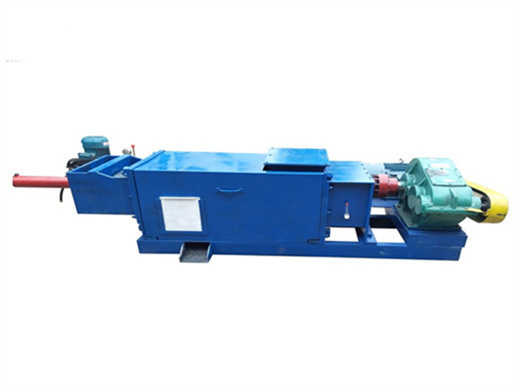

edible oil pressing machines costs in malawi | Strong

- Usage: palm oil

- Voltage: 220V/380V

- Power (W): 25kw

- Model: small oil press

- Weight: 2000kg

- Dimension (L*W*H): 2050*1350*2000mm

To meet the international industry’s standards for edible oil, the crude palm oil produced by oil mills should be refined in palm oil refinery plan t. Palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been rooted in grain and oil equipment manufacturing for 37+ years. It has a modern production base of 100,000 square meters, equipped with cutting-edge equipment such as laser cutting machines, fully automatic welding robots, CNC precision machining centers, and an annual production capacity of more than 200 large-scale edible oil

Palm Oil Processing Production Line

- Type: cooking oil extraction machine

- Production capacity: 5-500 TPD

- Weight: 500 TONS

- Voltage: 440 V

- Certification: ISO,CE

- After-sales service provided: Engineers available to service machinery abroad.

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

The Batch type is the ideal choice for small-sized palm oil production (1-20TPD), while the Semi-continuous Refinery plants are the best choices for middle-large size production lines (20-50TPD), a fully continuous refinery line(50-600TPD) is most used in large palm oil production plants.

Palm Oil Mill Plant Production Line - Hongde OIL MACHINE

- Raw Material: palm

- Production capacity: high

- Power ( W): 18.5 KW

- Voltage: 220V, 380V or other

- Dimension (L*W*H): 900 *850*1550mm

- Weight: 1000kg

We can offer you a whole line of palm oil pretreatment equipment, palm oil extraction machines, and palm oil refinery machines, and build a palm oil turnkey project from A to Z for you. And we sell single machines too, palm fruit oil pressing machines, palm fruit crushing machines, palm fruit oil fraction machines and so on. GET A QUOTE

The Palm Shell Kernel Separator Machine is an indispensable component of the complete palm kernel oil production line, designed to efficiently separate palm kernel shells from the kernel for further processing. This innovative machine plays a crucial role in maximizing the yield and quality of palm kernel oil while minimizing waste