Kembara Insan / Engineer's Blog: Palm Kernel Oil Extraction

- Type: palm oil press

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100% oil press machine

- Voltage: 220V/380V/440V

- Weight: 950KG

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Power (W): 5.5 ~ 18.5 KW

- Country: tanzania

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Palm Kernel Crusher Plant Operation and Economic Feasibility

- Type: palm oil processing machine

- Production capacity: 40-50 kg/h

- Voltage: 220 V/380 V

- Residual oil proportion: 1%

- Weight: 250kg

- Dimension (L*W*H): 1200*800* 1160mm

The average palm kernel oil extraction rate is 45.63% and Figure 8 shows the palm kernel oil extraction rate trend in Malaysia (MPOB, 2021). Figure 6. Typical filter press structure for crude palm kernel oil clarification. Load cells Moving head Filter cloth support upper rails Cloth wash spray bars Fixed head Parallel hydraulix cylinders

5tph palm kernel cracking and separating machine project and 1tph palm kernel oil processing plant project in Uganda. 2tpd batch type edible oil refinery plant project in China. 1tph palm oil processing mill plant project in south africaia. 500kg/h palm oil and palm kernel oil processing plant project in Ghana. 2TPH palm kernel oil mill plant in Liberia

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

- Usage: palm oil

- Production capacity: 50-60KG/H

- Voltage: 380V/50HZ

- Main components: Motor

- Weight: 880 KG

- Dimension(L*W*H): 900*750*1400mm

Palm fruit or palm kernel for edible oil has been processed in Africa for thousands of years, and the oil produced, highly colored and fragrant, is an essential ingredient in one of the traditional African cuisine. PALM KERNEL OIL PROCESSING PROCESS. Mechanical extraction processes are suitable for both small, medium and large capacity operations.

Relatively high oil content had been reported by [18] for avocado pear (74-75%), [21] for oleander seed (60-65%), [22] for Almond nut (50%) and [17] for palm kernel (44-53%).

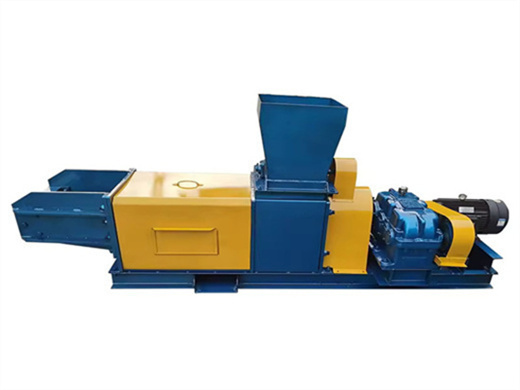

PALM KERNEL OIL PRESSING MACHINE

- Type: cooking oil extraction machine

- Production capacity: 80-150 kg/h

- Power (W): 5.5 kW

- Voltage: 380 V/50 HZ

- Dimension (L*W*H): 1700*1100*1600 mm

- Weight: 1200 kg

A palm oil refinery normally has a capacity of 50-1500T/D. Some of the refinery’s machines include a magnetic drum, cleaning sieves, crusher, flaker, and puffing machine. We have designed and manufactured three types based on the degree of automation to match the refining requirements of different outputs, and you can choose the most suitable one according to the actual situation and requirements of your own crushing plant.

artisanal palm oil sector and the domestic red oil consumption in Cameroon, open a window for contracted-farmers not to respect their contract, and process their FFB at home or to sell the fruits to artisanal mills. 2. Industry-smallholders partnerships in Indonesia The main oil palm production system in Indonesia is also based on the NES scheme.

Digester and Pressing : VIRIDIS Engineering Sdn Bhd

- Raw Material: palm

- Production capacity: 100% oil press machine

- Power (W): 5.5 ~ 18.5 KW

- Voltage: 220V/380V/440V

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Weight: 950KG

Palm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Digester Machine. The fruits are then digested in the digester.

5.3 Traditional method of palm kernel extraction. Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when