JMDS-Multi-disk screw press - Jorsun Environment

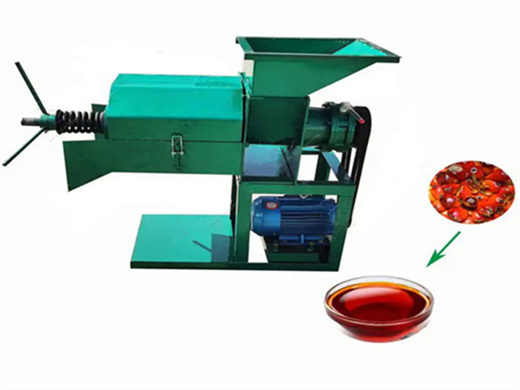

- Type: palm oil press

- Usage/Application: palm fruit, palm kernel

- Production capacity: 60%

- Voltage: 220V/380v

- Oil type: cooking oil

- Weight: 200 KG<br /Main components: motor, PLC, others

- Dimension (L*W*H): 700*1000*1300mm

- Country: south africa

Multi-disk screw press solves the technical problems of previous generations of sludge dehydration equipment, such as easily blocked, unable to deal with low concentration sludge and oily sludge, high energy consumption, complex operation, etc.

Sludge Dewatering - VIRIDIS Engineering Sdn Bhd

- Type: palm oil processing machine

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Main components: gear, bearing, gearbox

- Weight: 685 KG

- Dimension (L*W*H): 2010*600*1170mm3

As part of this proposal, we have included for the supply of a dewatering system to reduce the DAF sludge and aerobic sludge water content. This is likely to be either a screw press or a centrifuge. The sludge from the DAF and MBR are combined in the Sludge Tank and mixed to produce a homogeneous solution.

The sludge dewatering screw press machine, (which is) a specialized type of screw press machine designed specifically to reduce the moisture content in sludge or other solid materials with high moisture content, is often used in wastewater treatment applications, agriculture, and other industries where separating liquids from solids is crucial.

Multi-disc Screw Press for Palm oil sludge dewatering

- Usage: palm oil

- Production capacity: 5-100T/DAY

- Voltage: 110V/220V

- Main components: Motor

- Weight: 13 KG

- Dimension (L*W*H): 530*270*350mm

principles of force-water homo-direction, thin-layer dewatering, proper pressure and extension of the sludge dewatering path. The new equipment, more advanced than the traditional dewatering equipment which are easily blocked, unsuitable for low-concentrated sludge and oily sludge, of high consumption and difficult to operate, well eliminate

The press geometry is suitable for dewatering a wide range of municipal sewage sludge types, from digested sludge, stabilised and thickened surplus sludge to fresh primary sludge. Even thin surplus sludge can be dewatered without prior thickening using the HUBER Screw Press Q-PRESS®.

Esmil Multi-Disk Screw Press for Wastewater Dewatering

- Type: cooking oil extraction machine

- Production capacity: 1-100 TON per day

- Dimension (L*W*H): 2000*1500*800mm

- Voltage: 380V/415V three-phase

- Weight: 1500 kg

- Main components: motor, engine

The MDQ screw presses are operated as a part of mechanical dewatering systems. The standard system can include: the MDQ screw press, an external pump for initial sludge supply, a polymer feeder solution dosing pump and a dewatered sludge conveying equipment. Multi-Disk Screw Press MDQ/MDC Design. Dewatering Drum Design

The C-Press is the latest result of more than 20 years of experience in designing and manufacturing screwpresses. By combining multiple ANDRITZ Separation dewatering technologies, its uniquely compact design and purpose-developed features enable easy, operatorfree sludge dewatering operations together with low energy and maintenance costs..

SLUDGE SCREW PRESS - EQUIPWATER

- Raw Material: palm

- Production capacity: 300-4000kg/h

- Dimension (L*W*H): 1400*950*1250mm<br / Weight: 1280 KG

- Voltage: 380V

- Main components: not including spare parts

- Oil type: cooking oil

SLUDGE SCREW PRESS. Cost-effective Sludge Thickener Dewatering Solution. To obtain the best performance in terms of sludge dewatering, the two machines can be installed one after the other: first the thickener to obtain a concentration, variable depending on the model from 4 to 8% of SS, and to follow the dewater screw press for dewatering,

The Sludge Dewatering Screw Press can be widely used for various wastewater treatment systems such as municipal, petrochemical, chemical fiber, paper making, pharmaceutical, leather and other industrial water treatment system. Also it can be used for Dairy Farm Manure Treatment, Palm Oil Sludge, Septic Sludge, etc.