Small Scale Cold Oil Press Machine - Peanut Oil Press Machine

- Type: peanut oil press

- Usage/Application: peanut, groundnut

- Production capacity: 10-20 kg/h

- Voltage: 220 V

- Main components: Motor

- Weight: 65kg

- Dimension (L*W*H): 690*340*760 mm

- Country: lusaka

Small Scale Cold Oil Press Machine This oil press suitable for cold and hot pressing, adopts the principle of multi-stage gradual compression to increase the pressure in the barrel quickly and thus maximizing the oil output. Oil output rate is greatly improved for its unique design of the oil guide groove in the barrel.

Peanut Oil Press-- Integrated Screw Oil Press for Both Cold

- Type: peanut oil processing machine

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Main components warranty: 2 years

- Weight: 230KG, 230KG-250KG

- Dimension (L*W*H): 1700*1300*1600

Automatic Peanut Oil Press Machine. Automatic peanut oil press machine is a kind of superior oil pressing machine nowadays in the market. It is used for processing cooking oil from various oil bearing materials such as peanuts, soybeans, sunflower seeds, rapeseeds, oil palm, sesame seeds and so on.

With its high oil yield and versatility, this machine is perfect for all types of food processing enterprises and oil mills, allowing you to stand out in a competitive market. Ideal for large-scale industrial production or small-scale family workshops, our equipment meets diverse customer needs and is the ideal choice for the future of oil

Set up Your Own Small Oil Pressing Production Line at Lowest Cost

- Usage: peanut oil

- Voltage: 380V

- Appearance: Vertical

- Customized: customized

- Press series: according to different specifications

- Press materials: All oils

So what equipment is required for a small scale oil production line? Vegetable Oil Processing Machine for Sales. Generally, a complete small oil pressing line is made up of cleaning equipment, cooker, oil press machine, oil filter press, edible oil refinery machine and more. But, all the equipment should be choose based on the properties

The Cold Oil Press Machine is designed to extract high-quality oil from various seeds and nuts without applying external heat. Equipped with a disc fine filter, the particle impurities in the crude oil are removed rapidly. Cold oil press machines can also be used for hot pressing. Ideal for small to medium-scale oil production.

Peanut oil production line | Groud nut oil press - Hongde Oil

- Type: cooking oil extraction machine

- Production capacity: 200 kg/h

- Dimension (L*W*H): 45*18*30 cm<br /Weight: 42.5 KG

- Voltage: 220 V

- Main components: Motor

- Oil type: cooking oil

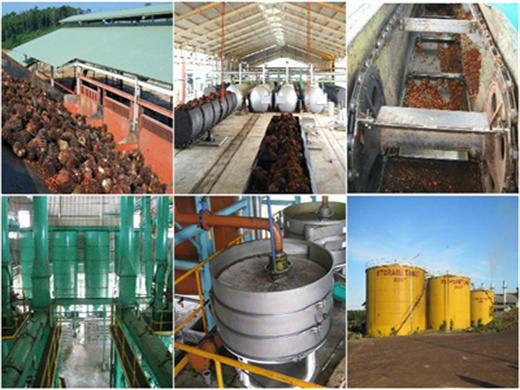

The peanut pretreatment processes include cleaning, and separating of hull & kernels. According to pressing temperature, there are two peanut oil pressing technologies: hot pressing and cold pressing. Crude peanut oil refining inludes degumming, deacidification, deodorization. How to produce peanut oil? Processing Steps of Peanut Oil Production

The Peanut Oil Press Machine is a specialized equipment designed to extract oil from peanuts and other oilseeds with precision, efficiency, and minimal waste. It integrates advanced pressing technology and robust construction, making it suitable for peanut oil production lines on different scales, from small farms to industrial oil processing

Choose Right Groundnut/Peanut Oil Extraction Machines

- Raw Material: peanut

- Production capacity: 50-1000 kg/h

- Dimension (L*W*H): 3740* 1920*3843 mm, 3740*1920*3843 mm

- Voltage: 380V/440V or required

- Weight: 9160 KG, 9160 kg

- Main components: Pressure vessel

Small Screw Oil Press Machine - suitable for medium and small scale groundnut oil production line Hydrualic Oil Press Machine - suitable for high quality oil production line or cold pressing line The peanut oil press machine provided by Our Machinery has high quality and good production efficiency.

For medium-sized peanut oil production line, the processing capacity is generally 10TPD-50TPD. The main way to obtain the gross oil by pressing. However, in order to further improve the quality of the crude oil, we will add cleaning equipment such as magnetic separator, vibrating cleaning sieve, wind separator, etc., to remove impurities such as leaves and metals from the raw material before steaming and pressing. This will further improve the quality of the oil and reduce the wear and tear on the pressing equipment. At the same time, after the press, we will add more perfect gross oil cleaning equipment.