Palm Kernel Oil Press Machine, Solution for Small-Scale Palm

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

- Country: botswana

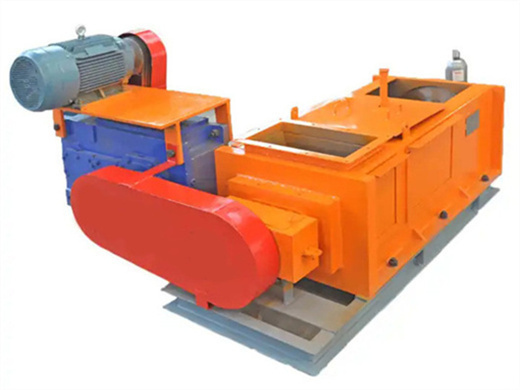

The complete small-scale palm kernel oil processing line includes a cleaning machine, roaster machine, screw conveyor, palm kernel oil expeller machine, and press filter. The compact structure, excellent performance, low power consumption, and ease of operation make this processing line an ideal choice for both commercial enterprises and small

Screw Palm Oil Press Machine, Oil Pressing Plant for Sale

- Type: palm oil processing machine

- Production capacity: 7.5w

- Voltage: 220V/380V/440V, 220V/380V/440V

- Main components: Motor

- Weight: 1100 KG, 1200kg

- Dimension (L *W*H): 1700* 1300*1750mm, 1700*1300*1750mm

After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine. Besides, nuts and fibre or press cake will also be discharged as palm oil pressing residues. Palm Oil Pressing Machine (Oil Extraction)

A screw is a kind of small oil press that expelling oil seeds through a confined cavity that is similar to barrel. Crude materials enter one side of the expeller and waste items leave the other side. The machine uses grinding and constant pressure from the screw drives to move and pack the seed material.

Small Scale Oil Presses(1 to 5 Ton/day)

- Usage: palm oil

- Production capacity: Hour

- Voltage: 220 V/380 V

- Main components: PLC

- Weight: 700 KG

- Dimension (length x width x height): 1700*1100*1600 mm

Oil is a valuable product with universal demand, and the possible income from oil extraction is therefore often enough to justify the relatively high cost of setting up and running a small scale oil milling business. Small Scale Oil Presses(1 to 5 Ton/day) We sell advanced screw oil presses (or Extruders) known for their ease of operation

For small-scale palm processing farmers, Dingsheng Machine has designed single-screw and double-screw palm fruit oil press, which can process 1ton, 5 tons, 10 tons and 15 tons of palm fruit per hour. Reliable palm oil press machine with simple operation, gaining a good reputation in Africa and South America.

BEST Screw Oil Press for Sale,Ideal C

- Type: cooking oil extraction machine

- Production capacity: 1-50 kg/h

- Dimension (L*W*H): 840 *240*540 mm

- Voltage: 220 - 240 volts

- Weight: 65 KG

- Warranty: 2 years

BEST screw oil machines are suitable for processing a wide variety of vegetable oil seeds and nuts.. Oilseeds & Nuts the screw oil press can process: Mustard Seeds, sunflower seeds, Rapeseed, soya beans, Canola Seeds, Soybean, Castor Seeds, Shea nuts, Coconut or Copra seeds, Karanja Seeds, Cotton Seeds, Jatropha seeds, Corn Germ, Neem Seeds, Flax Seeds, palm kernel, Groundnuts, Sesame

This series of small palm oil press machine is an oil making equipment developed by our company for the efficient extraction of grease from palm fruit, also called palm oil expeller or small palm oil making machine. It is widely used in small production line of palm oil. Like the general-purpose oil press, it is also a screw press.

palm oil line

- Raw Material: palm

- Production capacity: 10 tons to 5000 tons per day

- Dimension (L*W*H): According to production capacity

- Voltage: 380 V

- Weight: 10000 KG

- Main components: motor, pressure vessel, pump, bearing, motor

There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

In order to meet the needs of small-scale palm oil extraction workshop, Our Machinery has successfully developed this complete small scale palm oil refinery plant to achieve the integration of flow of dephosphorization, degumming, deacidification, dehydration and decolorization.