PHYSICAL REFINING OF SUNFLOWER OIL

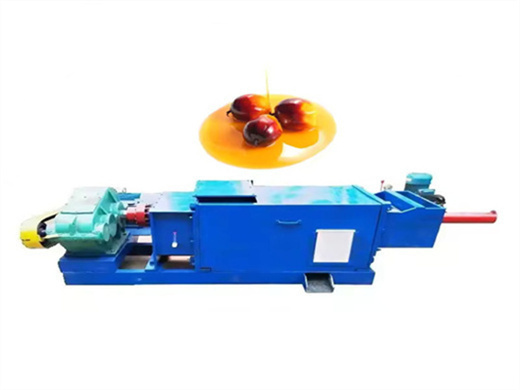

- Type: sunflower oil refining equipment

- Usage/Application: sunflower

- Production capacity: 0.8 ~ 1 T/24 hours

- Voltage: 380 V

- Main components: others

- Weight: 150KG

- Dimension (L x W x H): 920*390* 750mm

- Country: johannesburg

environmental friendly process (no soapstock to be treated, splitted) but more sensitive to the crude oil quality. Physical refining of sunflower oil is discussed in details. Recent developments in the field of processes, equipment and control have made possible to refine by physical way the high phosphatide containing seed oils as well.

What Are Sunflower Oil Refining Process Techniques?

- Type: sunflower oil refinery machine

- Production capacity: high

- Voltage: 220V/380V

- Main components: motor, pressure vessel, pump, gear, bearing, motor, gearbox

- Weight: 1100 KG

- Dimension (L*W*H): customization

Vital Strategies: Maximizing Efficiency in Sunflower Seed Oil Refining. Refined Sunflower Oil Production Process. The first step in refining control is to precisely manage temperature and time in each stage of production line. The temperature settings in steps like decolorization and deacidification must be precise to ensure that no unnecessary

Sunflower Oil Refining Equipment List; Sunflower oil hydration and degumming equipment: 1. Hydration tank (intermittent, same as alkali refining pot) 2. Vacuum dryer 3. Desolventizer (dedicated to remove residual solvents from leaching branched hairy sunf

How is Sunflower Oil Processed?

- Usage: sunflower oil

- Production capacity: 5TPD-100TPD

- Voltage: 220V/110V, 110V/220V 50/60Hz

- Main components: motor, bearing

- Weight: 8 KG

- Dimension (L*W*H): 380* 152*320mm

Sunflower oil processing involves many process that will decide the equipment and machinery for a sunflower oil processing plant. For small scale sunflower oil processing line, the equipment may be relatively simple and easy to operate. Of course, the investment cost for small scale oil factory is low but the profits is considerable.

1. Sunflower oil pre-press process Sunflower→ Magnetic seperating( Metal impurities)→ cleaning→ husking→ flaking roll→ Cooking→ pressing workshop First, use magnetic separator, de-stonner and vibrate cleaning sieve to remove metals, small stones, impurities from sunflower raw seeds. Second, use husking machine to remove husks, separating screen to separate husk and sunflower kernel

Efficient Sunflower Oil Production Machines

- Type: cooking oil refining machine

- Dimension (L*W*H): 1200*1300*1900

- Main components: Motor, pump, Gear

- Weight: 2350 KG

- Oil Type: Cooking Oil

- Raw Material: Sunflower

Sunflower seed oil production does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil.

Crude Sunflower Oil Refining Machine: The Heart of the Refining Process . A Crude Sunflower Oil Refining Machine is the key piece of equipment in any modern vegetable oil processing plant. This machine is designed to remove impurities, toxins, and unwanted substances from crude sunflower oil, which is crucial for producing high-quality edible

Sunflower Oil Refinery Plant Process - Oil Expeller

- Raw Material: sunflower

- Production capacity: 10T-100T/D

- Power (W) : 11KW

- Voltage: 220V/380V

- Dimension (L*W*H): According to the actual situation

- Weight: 1000 kg

Bleaching. This is one the important stage in total refining process. Where the oil is heated to 100°C to 105°C and mixed with Bleaching earth chemical ( Acid Activated Clay) and also activated carbon in a vessel under vacuum at 70 mmHg where the stirring continues for specific designated time and then filtered the oil to remove the clay and carbon.

The Refining Process. When it comes to refining sunflower oil, the process is quite straightforward. First, the sunflower seeds are cleaned and sorted to remove impurities such as dust, sand, and other foreign matter. Then, the oil is heated to a high temperature to separate the oil from the unwanted components.