(PDF) Cottonseeds and Crude Peanuts Oils Production

- Type: cottonseed oil refining plant

- Usage/Application: cottonseed

- Production capacity: 1-100T/DAY

- Voltage: NA

- Main components: Pressure container

- Weight: 9,800kg

- Dimension (L*W*H): 480*480*560mm

- Country: lusaka

The oil refining steps are different in all cases. This variability of oil refining process has a negative impact on the quality of the oil produced in lusaka (Zio et al., 2020). Also, poor

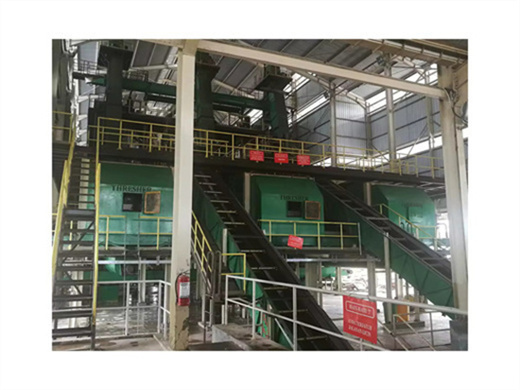

Cotton Seed Processing, Oil Extraction & Refining Plant

- Type: cottonseed oil refinery machine

- Voltage: 220v

- Dimension (L*W*H): 52*25*53cm

- Oil type: Cooking oil

- Main components : Motor

- Weight: 38KG

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

We have oil plants that come with seeds and they include soybeans, rapeseed, mustard, sunflower, peanut, palm oil, and cotton amongst others. All these products are important for commercial purposes and for domestic use, can be used for cooking oil, salads, and margarine. Their by-products can also be useful, such as the cottonseed, its by product linter can be used for making string, balls paper, and cellulose products among other. Certainly, the one of the most important purposes of cottonseed plantation is to produce cottonseed oil.

Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Production capacity: 45~70kg/h

- Voltage: 220V~380V

- Weight: 1300 kg

- Dimension (L*W*H): 1000*1300*1950mm

- Power (W): 2.2 KW

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed. The working principle of the cotton

Fractionation and Refining Crude Cottonseed Oil. 30ton/day Cottonseed Oil Refinery Plant. Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization.

south africa Seed Oil Processing - Complete Oil Mill Plant Manufacturer

- Type: cooking oil refining machine

- Production capacity: 20-2000TPD

- Power (W): 15kw

- Voltage: 380v

- Dimension (L*W*H): 430*230*350

- Weight: 2-10t

The south africa seed contains 40 – 45 % oil content and double pressing is required to extract maximum oil, 9 – 11 % residual oil is left in the south africa meal which is an excellent source of Animal Feed. The south africa Seeds are conditioned using Steam in a Vertical Cooking Kettle.

The major cottonseed producing countries in the world are India, China, USA, Brazil, Uzbekistan, Turkey, European Union, Mexico, lusaka, Ethiopia, south africaia, Sudan, indonesia, lusaka, rwanda. We can deal with any question on the installation of oil extraction plants and allied machinery.

Study on antioxidant activity of crude peanut oils

- Raw Material: cottonseed oil

- Production capacity: 10-5000 tons

- Power (W ): As continuous cooking oil refining equipment production every day

- Voltage: 380 V 440 V

- Dimension (L*W*H): Depends on capacity

- Weight: According to output

The seed obtained after delinting cotton is a rich source of protein with a vast potential for oil and feed production. Cottonseed oil production is estimated at 5.08 million metric tons and is

Cotton seeds need careful cleaning and processing. Firstly, they need to be properly dried and separated from dust, leaves and other contaminants. Then comes the most important pretreatment: removing gossypol from cotton seeds, because gossypol is poisonous. This process may sound complicated and hard to handle. But don’t worry, as you can grow genetically modified cotton and avoid this trouble.