Soybean Oil Production Line-Soybean Oil Solvent

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 45 sets per year

- Voltage: 380V/440V

- Weight: 500TON

- Dimension (L*W*H): 1200*2800*1200mm

- Power (W): 30KW

- Country: lagos

The soybean oil production line includes the soybean pretreatment process, soybean pre-pressing process, soybean oil extracting process, and soybean crude oil refining process. Our advanced soybean oil equipment, such as solvent extractors and automatic control systems, ensures high yields and consistent quality of both crude and refined oil.

Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Type: soybean oil processing machine

- Voltage: 220 V/380 V/440 V

- Power (W):50kw

- Certification:ISO9001/CE/BV

- Weight:Depends on capacity

- Dimension (L*W*H):Depends on capacity

The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed. Soybean oil expeller mainly uses the change of screw pitch size and screw thread deep to reduce the volume between the screw pitch and the pressing chamber, the raw material

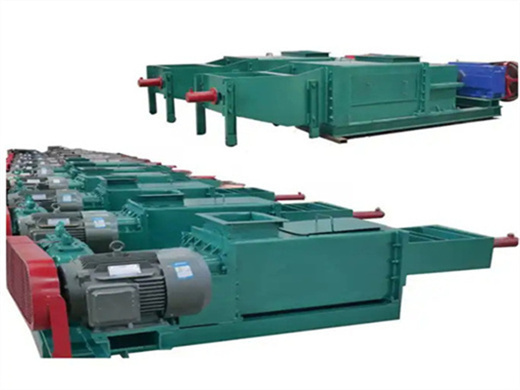

The main products include screw oil presses, solvent extraction equipment, refining equipment, etc., covering the complete production chain from soybean pretreatment, oil pressing to oil refining. The equipment design adopts advanced automatic control system, which is easy to operate and has the characteristics of high output, low energy

Soybean Oil Production Line

- Usage: soybean oil

- Production capacity: 100%

- Voltage: 380 V

- Weight: modified with capacity

- Dimension (L*W*H): various with capacity

- Power (W) : according to capacity

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil.

Dingsheng Machinery provides intelligent soybean oil processing and soybean by-product deep processing solutions covering the entire supply chain - soybean pre-treatment workshop equipment, soybean embryo leaching workshop equipment, soybean crude oil refining workshop equipment, soybean oil dewaxing, soybean protein isolate, soybean protein concentrate, soybean lecithin production line.

Soybean Oil Production Line - QIE Group

- Type: cooking oil extraction machine

- Production capacity: 1TPD-1000TPD

- Power (W): 25-44kw

- Voltage: 220/380V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

Soybean oil processing plant Soybean → Cleaning → Crushing → Softening → Flaking → Cooking → Pressing → Filtering Soybean oil solvent extraction plant soybean should be pretreated in soybean oil processing plant. It can produce high capacity soybean oil. Soybean Oil Refinery

Our soybean oil production line is designed to meet the international market's demand for efficient and sustainable production of soybean oil. This complex production line uses the most advanced technology to ensure that each step from soybean cleaning, crushing and extrusion to extraction and refining achieves optimal performance while

Soybean Oil Production Line-Soyoil Solvent Extracting Plant

- Raw Material: soybean

- Main components: Bearing

- Color and page: Multicolor

- Plate type: Flatbed printer

- Voltage: 380V/220V

- Dimensions (L*W*H): 2800*1300*1600mm

Soybean Pretreatment Process Soybean Cleaning Equipment. High efficiency vibrating screen is adopted here to remove the impurities, so as to effectively achieve the cleaning effect, ensure good operating environment and stability of production, and simultaneously improve the product quality.

Good soya bean oil refining process through the precise control of each step of the process parameters, can improve the soybean oil refining yield (96.5%), reduce the refining process loss, and effectively reduce the waste water, waste oil, waste soil and other pollution of the environment, and further reduce the production cost.