Soybean Oil Refining Machine in indonesia

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 1 ton/day

- Voltage: 220V/380V/440V

- Oil Full warranty service: Video technical support

- Weight: 0 KG

- Dimension (L*W*H): 4.26 *1. 55 *3.52 ft

- Country: indonesia

Soybean oil extraction equipment mainly includes a extraction system, wet meal desolvation system, mixed oil treatment system and solvent recovery system, and is used for large-scale edible oil production plants with oil treatment capacity of more than 20 tons per day.

Industrial Oil Soya Bean Processing Line in indonesia

- Type: soybean oil refinery machine

- Production capacity: 15-500 kg

- Dimension (L*W*H): According to different models

- Driving oil dosage: 10-150kg

- Voltage: 220V/380V

- Weight: 1000 kg

This is a turnkey soybean oil mill plant established in Africa for one of our customer, and this unit consists mainly of oil expeller, oil filtering equipment, cooking kettle, cleaning equipment, etc. It is a turnkey project with a raw material extraction capacity of 50 tonnes per day. If you are interested in starting your own soya bean oil

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil. What is

Complete Soybean Oil Extraction Plant Sent To indonesia

- Usage: soybean oil

- Production capacity: 100%

- Voltage: 220/380/400v

- Weight: depends

- Dimension (L*W*H)): depends

- Power (W): 5-100kw

The pressed gross soybean oil should be refined through a soybean oil refinery to obtain pure edible oil. Learn how to make multi-purpose soybean oil at low cost by soybean oil extraction machine manufacturers or suppliers at factory prices in Ghana, Zambia, Kenya, Uganda, indonesia and other soybean oil extraction machine projects.

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil. The physical pressing line requires raw materials to be carefully selected, and the soya bean is pre-treated through cleaning, crushing, softening, rolling and extruding.

Soybean Oil Production Line-Soybean Oil Solvent - Oil mill

- Type: cooking oil refining machine

- Voltage: up to specification

- Dimension (L*W*H): 1360*950*1170 mm

- Power (W): up to specification

- Weight: according to specification

- Certification: ISO9001

The soybean oil production line includes the soybean pretreatment process, soybean pre-pressing process, soybean oil extracting process, and soybean crude oil refining process. Our advanced soybean oil equipment, such as solvent extractors and automatic control systems, ensures high yields and consistent quality of both crude and refined oil.

How is soybean oil extracted? Therefore, the majority of commercially produced soybean oil relies on a mechanical and solvent extraction process ( 3 ). This process extracts the edible oil from the soybeans, and the finished product is known as a ‘refined, bleached, and deodorized’ (RBD) oil. What is Muskan Soyabean oil? Muskan Soyabean Oil […]

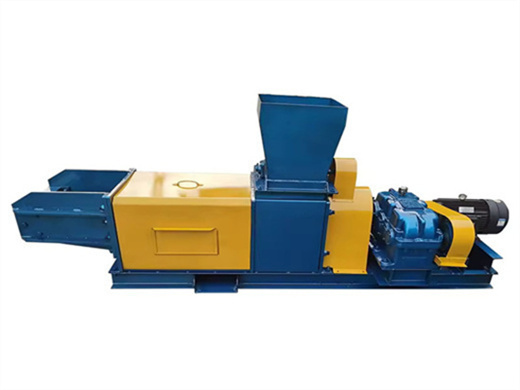

Soybean Oil Production Line

- Raw Material: soybean

- Production capacity: 50-800 kg/h

- Dimension (L*W*H): 520*220*280 mm

- Voltage: 220 V

- Weight: 1400 kg

- Main components: Motor

The soybean oil production line is a process in which soybeans are treated by pressing or solvent extraction method to obtain crude soybean oil and then refined to obtain edible soya oil. The two oil production methods have different application scenarios and advantages and disadvantages, please contact us to provide you with a more suitable

Complete Soybean Oil Production Plant Layout. The refining of soybean oil, a process that removes impurities and enhances its stability, is a crucial step in ensuring the oil's superior quality. With its demand steadily increasing across industries, the market for soybean oil and its refined products is poised for further growth.