Mini Soybean Oil Processing Unit

- Type: soybean oil refinery machine

- Usage/Application: soybean

- Production capacity: 400~600 kg/h

- Voltage: 220V/380V

- Weight: 2000kg

- Dimension (L*W*H): 1500*1600*2500mm

- Power (W): 18.5 kW

- Country: lesotho

The following video is about a small scale soybean oil mill project designed and built for one of our client in lesotho. It is a complete oil mill plant including oil extraction machine and crude oil refinery machine. Take this soya processing plant for reference if you are about to start your own soybean oil manufacturing business in India or

Small Edible Oil Refinery Plant

- Type: soybean oil refinery machine

- Fully/semi-automatic

- Production capacity: 1-500T/D

- Dimension (L*W*H): 5432*2636*2345

- Power (W): 70-150kw

- Voltage: 220V/380V

Mini/Small Scale Edible Oil Refining Plant Projects by Our Machinery. Every year, we will export and set up many edible oil refinery machine in different contries, including India, Ghana, Zambia, Australia, Jamaica, south africaia, Tanzania, Zimbabwe, Namibia, lesotho, the United States, etc.

Discover high-efficiency edible oil refinery machines designed for optimal oil purification and processing. Suitable for various oils like soybean, sunflower, palm, and peanut, these machines ensure premium quality oil with advanced refining technology. Enhance your production with our durable and cost-effective solutions.

soybean oil extraction in lesotho - oil extraction machine supplier

- Usage: soybean oil

- Production capacity: 10--1000TPD

- Voltage: 220V, 380V

- Weight: According to its capacity

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): Capacity

Our focus is on building efficient and effective soybean oil extraction factories that are tailored to your unique needs. We offer a comprehensive package of services, including consulting, planning, design, research and development, equipment manufacturing, installation, commissioning, and training. Our primary goal is to create maximum value for you and bring your vision to life.

Good soya bean oil refining process through the precise control of each step of the process parameters, can improve the soybean oil refining yield (96.5%), reduce the refining process loss, and effectively reduce the waste water, waste oil, waste soil and other pollution of the environment, and further reduce the production cost.

Manufacturer of soybean oil processing plant

- Type: cooking oil refining machine

- Production capacity: 6-8T/24H

- Dimension (L*W) *H): 2200*1650*1750mm

- Voltage: 220v/380v

- Weight: 1400 KG

- Main components: Motor, PLC

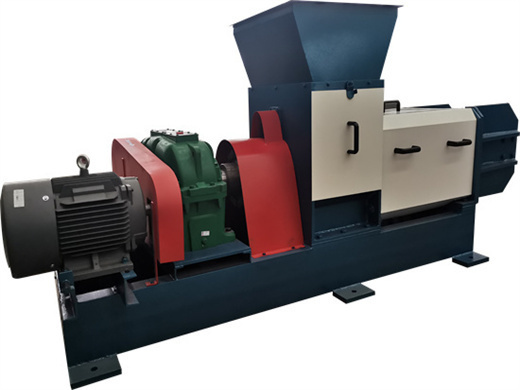

The main products include screw oil presses, solvent extraction equipment, refining equipment, etc., covering the complete production chain from soybean pretreatment, oil pressing to oil refining. The equipment design adopts advanced automatic control system, which is easy to operate and has the characteristics of high output, low energy

The soybean oil discharged from soybean oil press machine contains many useless and unhealthy substances and impurities. In order to produce high quality edible oil, the first step is to filter all the organic impurities. (Related equipment: Oil Filter Machine >>) Soybean Oil Refining Process

300TPD Soybean Oil Processing Machines Equipment

- Raw Material: soybean

- Voltage: 220V/380V

- Dimension (L*W*H): 1200 *400*900mm3

- Power(W): According to cooking oil refinery equipment capacity

- Weight: According to cooking oil refinery equipment capacity

- Material: 304 Stainless Steel

3. 300TPD Soybean Oil Refining Production Line Introduction Based on the traditional oil refining technology, has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality.

This soya & peanut oil pressing line with daily capacity of 15 tons oil pressing and 3 tons oil refining was set up in lesotho, adjacent to Ghana (See more about Soybean Oil Production Plant in Ghana). It is complete oil processing line that is composed of raw material pre-treatment section, oil pressing section, oil refining section and oil