Efficient Soybean Oil Refinery Process and Machines for

- Type: soybean oil refining equipment

- Usage/Application: soybean

- Production capacity: 50 kg per hour

- Voltage: 220-240 volts

- Oil thermostat: Temperature control 600 Watt

- Weight: 65 KG

- Dimension (L*W*H): 840*240*540 mm

- Country: zambia

The refining process of soybean oil batch refining line is carried out batch by batch. Soybean oil batch oil refinery machines is suitable for 1-30 tons/day small soybean oil refinery plant. The Pros of Mini Soybean Oil Refinery Plan: Compact Brilliance. The equipment composition of mini/small soybean oil refining line is shown in the below

How to Start Mini Soybean Oil Mill Plant | 1~30 Tons/Day

- Type: soybean oil refinery machine

- Production capacity: 100TPD

- Dimension (L*W*H): 12*7*7 feet

- Main Components: Others

- Main Components Warranty: Others

- Weight: 8000 KG

Estimates of the total cost range from $ 7,000 to as high as $100,000. For people who is going to start a mini or small soybean oil making business. It is absolutely the BEST choice. (Read more about Soybean Oil Business Plan >>) 1~30TPD Mini Soybean Oil Mill Plant. Mini Soybean Oil Mill Plant at Low Cost

For the ones who are planning to start soybean oil processing business of mini or small scale, equipment selection and matching is the very first step for the success of your business. Here we recommond you our best-selling equipment set for mini and small sized soybean oil processing factory, capacity ranges from 1 ton/day to 20 ton/day.

Interested in Setting up a Mini Soybean Oil Production

- Usage: soybean oil

- Production capacity: 40-500 Kg/h

- Voltage: 380V/50HZ

- Main components: Motor

- Weight: 160kg

- Dimension (L*W*H): 880x440x770mm

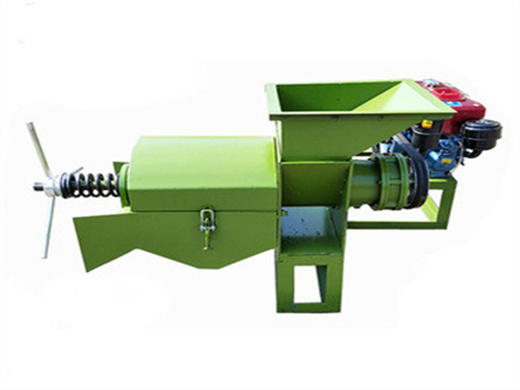

Moreover, mini soybean oil production assembly unit can process many other oil seeds, such as peanut kernels, rapeseed, cotton seeds, sunflower seeds, corn seeds, palm kernels, and sesame seeds. The automatic oil press machine is the most important equipment in the mini soybean oil production assembly unit, its components include the oil press

Small to Medium-Scale Soybean Oil Production: Capacity Range: Ideal for soybean oil mill plants with a capacity of up to 100 tons per day (TPD). Mechanical pressing equipment is generally more compact and requires a lower initial investment, making it suitable for small to medium-scale soybean oil mill plants. High Oil Content Soybeans:

What Equipment is Needed in the Soybean Oil Production Process?

- Type: cooking oil refining machine

- Production capacity: 100TPD

- Dimension (L*W*H): 2300*1630* 1920 mm

- Voltage: 380V

- Weight: 1300 kg

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

If the oil volume planned to be processed per day is more than 10 tons, Our Machinery recommends that you choose a small edible oil production line to process soybean oil, which can not only ensure the oil output, avoid some oil loss, but also control the investment budget.A small soybean oil production line includes cleaning sieve,rolling

Soybean oil making machine is the main machine to produce soybean oil.The full set of soybean oil making machine mainly includes: soybean oil pretreatment machine, soybean oil extraction machine and soybean oil refinery plant. As a professional manufacturer and supplier of soybean oil making machine, Henan Doing Company can provide you the turn key project of the whole soybean oil making machine range from 10 to 2000TPD.

Equipment to Start a Small Scale Soya

- Raw Material: soybean

- Voltage: 220V/380V/440V

- Dimension (L *W*H): 1200*400*900mm3

- Power (W): 10-50kw

- Weight: According to the cooking oil processing capacity

- Certification: ISO9001/CE/BV

You can have cheaper land if you buy/rent it in a rural area. The main thing that will consume most of the budget will be soybean oil mill machines. Generally, the cost of establishing a mini/small scale small scale soybean oil plant ranges from $5,500 to $35,000. Soybean Oil Mill Machines for Sales. Small Soybean Oil Mill Project Report - ABC

Oil grade: high; Processing Type: refined; Process: full continuous; Moisture and volatile: 0.08%; Physical refining has several advantages compared to classical chemical one: − improved yield − lower investment cost − less environmental impact (no soapstock to be. Physical refining of sunflower oil is discussed in details.