Manufacturer of soybean oil processing plant

- Type: soybean oil extraction machine

- Usage/Application: soybean

- Production capacity: 1-500 tons/day

- Voltage: 220V380V

- Oil type: Cooking oil

- Main components: motor, PLC, pressure vessel

- Weight: 300KG, 500KG

- Country: zimbabwe

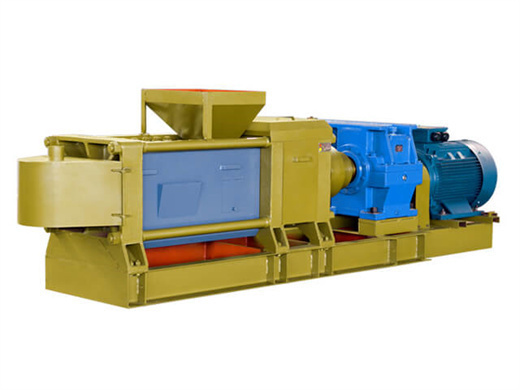

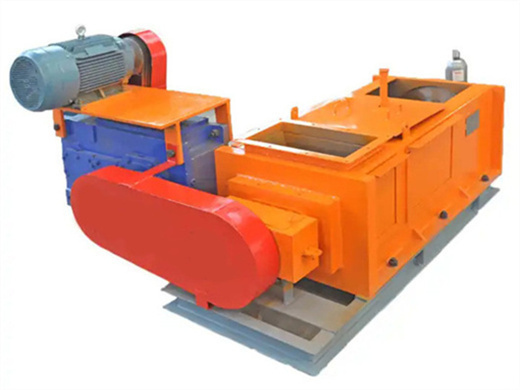

The main products include screw oil presses, solvent extraction equipment, refining equipment, etc., covering the complete production chain from soybean pretreatment, oil pressing to oil refining. The equipment design adopts advanced automatic control system, which is easy to operate and has the characteristics of high output, low energy

Soybean oil production line - Hongde Oil Machinery

- Type: soybean oil processing machine

- Voltage: Manual

- Dimension (L*W*H): 310*290*110mm

- Oil type: Cooking oil

- Main components : Gear

- Weight: 2.0400 kg

Pressed soybean cake→Solvent extraction system→D.T.D.C system→Condenser system→Recovery system→Crude soybean oil The soybean oil solvent extraction plant is an important part of soybean oil production line, which is designed to extract oil directly from pressed soybean cake. After soybean oil solvent extraction plant, the residual oil

New type soybean oil extraction technology utilizes solvent to extract oil out of soybean embryos through effects of wet penetration, diffusion and convert diffusion. The solvent capable of dissolving the fat separates soybean oil from the mixture of oil and solvent, and obtains crude soybean oil after solvent recycled.

Hongde is Soybean Oil Processing Plant Supplier-Hongde

- Usage: soybean oil

- Production capacity: 250-300 KG/H

- Voltage: 380V

- Weight: 2200 kg

- Dimension (L*W*H): 2000x1200x2500mm

- Power (W ): 3KW

The pre-treated soybean embryo flakes are sent to the soybean oil extraction plant, and the oil is extracted from the soybeans by using 6# solvent (n-hexane), and then the solvent is separated from the crude oil and recycled; the crude oil is sent to the soybean oil refining plant for refining. 3. Soybean Oil Production Line - Refining Section:

Soybean oil is a widely consumed vegetable oil derived from soybeans, one of the most important oilseed crops worldwide. It is known for its neutral flavor, versatile culinary applications, and nutritional benefits. Soybean oil is extracted from the seeds of the soybean plant through a process of mechanical pressing or solvent extraction.

Soybean Oil Processing Line Plant,Soya Bean Oil Press

- Type: cooking oil extraction machine

- Production capacity: 50 -3000TPD

- Power (W): As automatic heat press machine for palm production every day

- Voltage: 380v 440v

- Dimension (L*W*H): As automatic heat press machine production per day

- Weight : Depends on automatic heat press machine production

We provide high quality soybean oil processing line plant,soya bean oil press extraction refining machine plant,soybean 100TPD Palm Cake Solvent Extraction

Soybean Oil Solvent Extraction Process. Soybeans have a relatively low oil content (15-22%). To obtain more oil and considerable economic benefits, soybean extraction is generally used to produce soybean oil. The extraction method mainly uses solvent oil (hexane) to fully soak the treated soybean, so that the oil in the soybean is extracted.

BEST Soybean Oil Machine for Sale|Screw Pressing & Solvent

- Raw Material: soybean

- Production capacity: cold pressed oil expeller

- Power (W): depends on capacity

- Voltage: 220V/380V/ 440 V

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

Soybean Oil - Solvent Extraction Machine. The residue of solvent extraction plant is less than one percent. The users at that time can get soybean meal which contains high protein and can also be used for making the feed of animal. Due to this, lots of people are very much interested in solvent extraction plant of soya oil.

Extraction: It usually adopt an organic solvent that can dissolve the oil, through the material spray, soak, so that the oil will be extracted from the oil-bearing seeds. Refining is an essential process for a complete oil pressing line because there are still some impurities such as phospholipid s, FFA , pigment , odor , e tc in the crude oil.