Soybean Oil Production line – Liangli Machinery Equipment Company

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 98%

- Voltage: 220V/380V/440V

- Weight: 1200 kg

- Dimension (L*W*H): 1700* 1100*1600 mm

- Power ( W): 1.5 kw

- Country: botswana

2*- Crushing machine: Oil seeds are crushed into 6-8 pieces. In order to meet the requirements of crushing, the peanut is suitable for crushing with the moisture of 7% to 12%. 3*- Softening Process: The purpose of softening is to adjust the moisture and temperature of oil, and make it soft.

Soybean Oil Production Line-Soyoil Solvent Extracting Plant

- Type: soybean oil processing machine

- Production capacity: 100% cooking oil press/expeller

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L* W*H): Depends on its capacity

- Power (W): Depends on its capacity

Soybean oil is a vegetable oil extracted from the seeds of soybean, which has a mild nutty flavor and a better texture. It is one of the most widely consumed cooking oils, constituting about half of worldwide edible vegetable oil production.

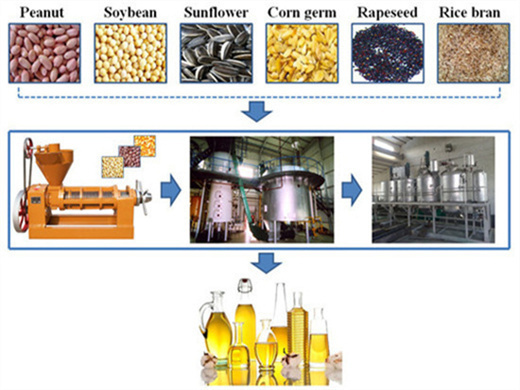

The soybean oil production line includes the soybean pretreatment process, soybean pre-pressing process, soybean oil extracting process, and soybean crude oil refining process. Our advanced soybean oil equipment, such as solvent extractors and automatic control systems, ensures high yields and consistent quality of both crude and refined oil.

Soybean Oil Production Line

- Usage: soybean oil

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

Dingsheng Machinery provides intelligent soybean oil processing and soybean by-product deep processing solutions covering the entire supply chain - soybean pre-treatment workshop equipment, soybean embryo leaching workshop equipment, soybean crude oil refining workshop equipment, soybean oil dewaxing, soybean protein isolate, soybean protein concentrate, soybean lecithin production line.

Brief Overview of Soybean Oil Production Line. 1. Advanced soybean oil extraction process, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automatic control. 3.

Turnkey Soybean Oil Equipment and Plants - CHEMSTA Group

- Type: cooking oil extraction machine

- After-sales service: online

- Appearance: Horizontal

- Voltage: 380 V

- Press Materials: Cooking Seeds, Rapeseed Seeds, Sunflower

- Press Series: Second

Soybean Processing Production Line(Preparation and solvent Extraction) Soybean is a kind of high value vegetable oil seed. Through different processing technologies, soybean can be processed into soybean meal (feed grade), full-fat soybean powder, edible soybean oil, soybean white flake, soybean protein concentrate(SPC), soybean protein isolate

Soybean oil pretreatment and pressing machine can highly increase oil yield, and it can be applied to other oil seeds as well, such as peanut, rice bran, sunflower seed, and rapeseed and so on. For different oil seeds, the pretreatment and pressing technology is various. The soybean oil pretreatment and pressing machine is efficient and energy

Edible oil production line, soyabean oil processing

- Raw Material: soybean

- Production capacity: 150-250 kg/h

- Dimension (L*W*H): 1950*1300*1900 mm

- Voltage: customer requirement

- Weight: 700 KG, 950 kg

- Core Components: motor, pressure vessel

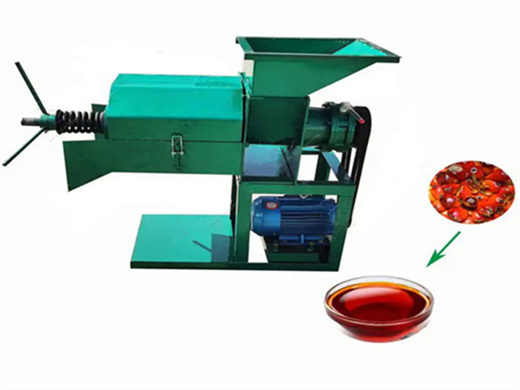

family-style workshops , small oil factory or large-scale which the capacity is 5T-50T.The oil production line includes oil seeds pretreatment, oil seeds pressing, crude oil refining and refined oil packing .We are also design different oil press line with different oil seeds such as soybean, peanut, sesame, rapeseed, sunflower, olive, palm

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil.