Sunflower Processing, Processing of Oil Seed and None-oil seed

- Type: sunflower oil press

- Usage/Application: sunflower

- Production capacity: 1-2000TPD

- Voltage: 220V

- Weight: 1300kg

- Dimension (L*W*H): 46*32*36 cm

- Power (W): 5. 5 kW

- Country: lagos

As the edible oil, sunflower seed oil primary uses are as salad or cooking oil or in margarine. Sunflower seed oil is cold-pressed. The cold-press entails minimal processing to produce a light, flavorful oil suitable for some cooking needs. Sunflower seed oil manufacture involves seeds cleaning, seed de-hulling, seeds grinding, seeds pressing

Seed Oil Press Machines for Sale-Industrial Oil Press

- Type: sunflower oil processing machine

- Production capacity: 1000kg/day

- Voltage: 380V/customized

- Main components: motor, pressure vessel, motor

- Weight: 250 KG

- Dimension (L*W*H): 2680 *680*1490mm

Suitable for both hot extraction and cold extraction; integrate pressing and filtering procedure saving time and energy; apply to over twenty oils seeds such as soybean, flaxseed, rapeseed, sunflower seed, etc. High oil yield and purer edible oil.

Sunflower seed oil is extracted from oil-type sunflower seed by the mechanical pre-pressing method with subsequent hexane extraction of the remaining oil in the meal. To be specific, oil-used sunflower seeds contain 45%~60% of the oil which is suitable for the pre-pressing and leaching method: In the 1 st , the raw seeds are pre-squeezed by

Growing & Pressing Your Own Seed Oil - Homesteading Family

- Usage: sunflower oil

- Certification: ISO, BV, CE, CE, ISO9001, BV, etc...

- keyword: cooking oil production

- Power consumption: ≤ 15KWh/T

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Residual oil in flour: ⪙ 1%

Hemp Seed – 35-40% oil within the seed. You can press it in the shell. The seed cake (or the leftover pulp after pressing the oil) is completely edible and can be consumed or fed to animals. Flax Seed – Another incredibly nutritious oil that has an edible seed cake. Sunflower Seed – 30-35% oil within the seed. You can get approximately

Note: YZS-30, YZS-60, YZS-70 multi-function oil presses are specially designed for manufacturing sesame oil, but they also suitable to extract oil from groundnut, sunflower seeds and rape seeds. Complete Oil Pressing Process. Sunflower seeds are of two types. One the non-oil seed which is usually eaten as confectionery just after being roasted

How Do You Press Sunflower Seeds For Oil? - Mikim Machinery

- Type: cooking oil extraction machine

- Product Type: Plant

- Outgoing Inspection Video: Provided

- Main components: Motor

- Main Components Warranty : 1 year

- Machinery Test Report: Provided

Now it’s time to start pressing the sunflower seeds for oil. Take your sunflower seed press and set it up according to the manufacturer’s instructions. Place the roasted sunflower seeds into the press and start cranking the handle or turning the lever. As you do this, the press will exert pressure on the seeds, extracting the oil.

We offer premium screw sunflower oil press with competitive price and reliable after services! Our seed oil presses are ideal equipment for small scale oil pressing production from 1TPD to 20TPD. It can process various oilseeds and nuts including sunflower seeds, ground nut, soya bean and so on. That is what we have and offering you our beloved customer. If you are want to start a small sunflower oil manufacturing plant. This mechanical oil press will be your best choice!

Sunflower Oil Press & Oil Extraction Process - Site

- Raw Material: sunflower

- Production capacity: 100% seed oil production machine

- Power (W): 5. 5 kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2500*1600*2500

- Weight: 1300kg

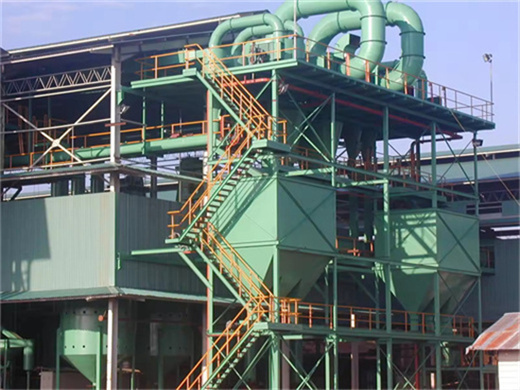

Sunflower oil can be extracted during the solvent extraction process using chemical solvents or by a sunflower oil press (screw press) used to squeeze the oil directly from sunflower seeds by crushing them. This method of cold-pressing sunflower seed oil under low-temperature conditions is a preferred method for those seeking an extraction

Sunflower Seeds. Read: Advantages and Disadvantages of GM Crops. Pressing: The heated meal is fed into a screw press which progressively increases the pressure from 60 kilopascals (kps) to 950kps, 206kps, to 850kps as the meal is passed through a slotted barrel.