Soybean oil Pressing Process & Equipment Selection

- Type: soybean oil press

- Usage/Application: soybean

- Voltage: 220v-380-415v

- Power (W): according to capacity

- Certification: ISO/CE/ISO9000

- Weight: different according to capacity

- Dimension (L*W*H): 1610x615x1260mm

- Country: mozambique

Pressing stage: Soybeans are pushed into the press screw barrel by the screw, and with the rotation of the screw, soybean oil is squeezed inside the barrel. Due to the spiral shape of the screw, the oil is squeezed out during the gradual pressurization process and discharged through the slag outlet.

100-500 Tpd Oil Refinery Machine Supplier in mozambique

- Type: soybean oil processing machine

- Production capacity: 12~90 kg/h

- Voltage: 110v/220v/380v

- Core Components: Engine oil

- Weight: 260 KG

- Dimension (L*W*H): 800*750* 960 mm

Complete Soybean Oil Extraction Plant Sent to mozambique. QIE Machinery is a professional soybean oil extraction machinery manufacturer and supplier in China, with a professional R&D team and project managers, providing the turnkey solution for home use single machine soybean screw oil press and Soybean oil extraction machine plant.

Specification:Cold Press Oil Mill MachineAfter-sale services:Offering installation and debugging,1 year quality warranty period; Expanding,Extraction,Refinery:Patent No. Oil Press Machine6YL Series Oil Press Machine is an advanced oil screw press characterized by its high oil output rate with good quality, simple design

Design, Development and Testing of a Screw Press Expeller - KUPDF

- Usage: soybean oil

- Voltage: 380V

- Power (W): 39kw

- Material: 304 Stainless Steel

- Dimension (L*W*H): 1500*900*1900mm

- Weight: 200kg

The objectives of this work are: to design a small scale screw press oil expeller for palm kernel (Elaeis guinensis J) and soybean (Glycyrrhza lepidota) oil extraction; to fabricate the components of the expeller based on the design specifications and; to test the expeller after fabrication and assembly of the components.

Soybeans are among the most widely cultivated crops globally, used in various industries from food production to biofuels. Processing soybeans into oil, meal, and other products requires specialized machines, each designed for different stages of the production process. Whether you’re a small farm operation or a large-scale industrial plant, it’s essential to choose the right machinery to suit your processing goals. In this article, we’ll explore the different types of soybean processing machines, the factors you should consider before purchasing one, and how to make an informed decision.

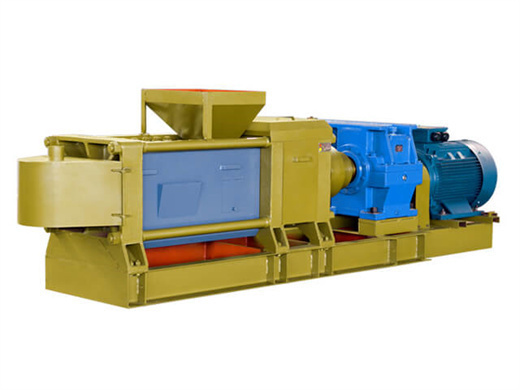

Soybean Oil Press

- Type: cooking oil extraction machine

- Main components: Bearing, motor, gear

- Dimension (L*W*H): 4875t1828t1985

- Power: 170 HP

- Weight: 14000 KG

- Fields of Oilseed Extraction: Cooking, Cotton, Sunflower, Cooking, Cooking, Sunflower

Working Process of a Soybean Oil Press 1. Soybean Preparation: Soybeans must be cleaned to remove impurities like stones, dust, and dirt. For some oil presses, soybeans are dehulled, crushed, and conditioned (heated) to improve oil extraction efficiency. 2. Feeding: The prepared soybeans are fed into the oil press machine through a hopper. 3.

The main products include screw oil presses, solvent extraction equipment, refining equipment, etc., covering the complete production chain from soybean pretreatment, oil pressing to oil refining. The equipment design adopts advanced automatic control system, which is easy to operate and has the characteristics of high output, low energy

6YL-120 screw model cold oil press machine-Henan Lewin

- Raw Material: soybean

- Production capacity: 45 sets per year

- Power (W): 30KW

- Voltage: 380V/440V

- Dimension (L*W*H): 1200*2800*1200mm

- Weight: 500TON

Bar press system can press the material evenly, and reduce the oil residue to improve the oil yield. 4.Our squeeze screw is longer and thicker, it can press material thoroughly to improved oil yield. 5.L-shaped automatic feeding system, which can feed oil cake into hopper directly, press oil cake secondly to improve the oil yield.

Along with maintenance- and operator-friendly packages, the systems can press over 300 metric tons per day (MTPD) in a single machine with residuals as low as 5% when paired with Anderson’s extrusion technology. With minimal modifications, the Anderson Lion Expeller oil press can change from one oilseed application to another, allowing for