automatic palm kernel oil expeller machine price in Cameroon

- Type: palm kernel oil press machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-500T/D

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Power (W): 5.5-22KW

- Country: cameroon

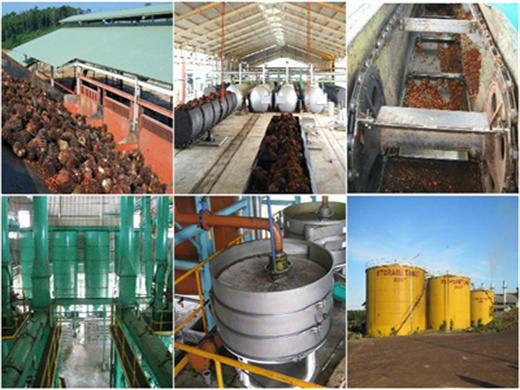

We are a professional Palm Oil Processing Machine manufacturer. We can provide palm oil pressing machine, small and large scale palm oil processing plant, automatic palm oil mill plant, Palm Oil Refinery machine and palm oil fractionation plant.

palm oil line

- Type: palm oil processing machine

- Production capacity: cooking oil extraction machine

- Voltage: 380V, depends on capacity

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity , depends on capacity

- Power (W): depends on capacity, depends on capacity

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Our Automatic double-shaft palm kernel oil press machine is designed to meet the needs of modern palm kernel oil production, with capacities ranging from 10 TPD to 100 TPD. It features a large processing capacity, high oil yield, and long service life.

Palm Kernel Oil Expeller for Cold Pressing of Palm Kernel Oil

- Usage: palm oil

- Production capacity: 140-280 kg/h

- Voltage: 380 V/415/440 V

- Main components warranty:1.5 years

- Weight:1000kg

- Dimension (L*W*H): 1800* 1300*1680

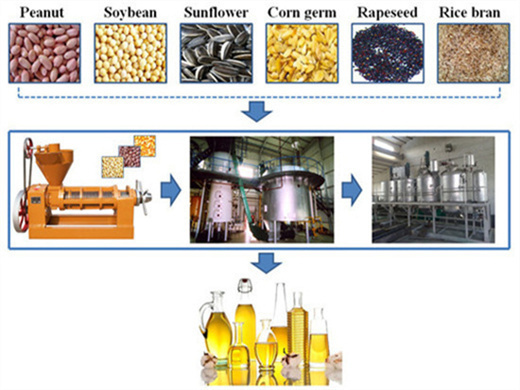

Palm Kernel Oil Press Machine Applications. Our palm kernel oil press is suitable for pressing high-oil-content oilseeds such as shelled peanuts, tea seed kernels, sunflower kernels, cottonseed kernels, rapeseed kernels, walnuts, rubber seeds and peeled soybeans at room temperature or at low temperature.

You can use a screw oil press to squeeze palm kernel oil, but you need to use an enhanced screw oil press. Because palm kernels are relatively hard, more wear-resistant snails and larger motors are needed to squeeze out palm kernel oil. Generally there are two models, 6YL-95A and 6YL-130A. The output of 6YL-95A palm kernel oil press is 200kg/h

Palm kernel oil processing machine

- Type: cooking oil extraction machine

- Production capacity: 100TPD castor oil plant

- Power (W): depends on capacity

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

The pressure then extracts the oil. The machines are popular for large-scale operations. They are favored because of their high-efficiency oil extraction. Cold press palm kernel oil machines. Cold pressing machines extract palm kernel oil without using heat. They do this by applying pressure to the kernel seeds.

This palm kernel oil extraction machine is specially designed for pressing palm kernel oil, according to the hard properties of palm kernels. It uses the most accepted palm oil processing technology in the world to obtain palm kernel oil. This type of palm kernel oil press has the characteristics of reasonable structure, convenient operation

6YL-130 Palm Kernel Oil Press Machine

- Raw Material: palm

- Voltage:380V/Customized

- Main components:Motor,pump,others

- Weight:8000KG

- Oil type:Oil rap seed oil, tea seed oil, basil oil, SESAME OIL, pine nut oil, sunflower nut oil, OLIVE OIL, Oil

- Product Raw material: soybean/sunflower/cotton seed/mustard/grain/sesame/peanut/copra

Ⅰ. The 6YL-130 Palm Kernel Oil Press Machine Introduction 1. Screw Oil Press Machine Description. The screw oil press is an oil press that makes full use of the screw driving force to extract oil from the oil to increase the oil output. The structure is simple and the functions are user-friendly. It is suitable for cold pressing and hot pressing.

4Main Feature of double shaft screw palm kernel shaft oil press machine (low cold press) 1)Double shaft screw oil press machine a. no smooth-bore engagement screw pair technology, b.strengthen promoting, c.inner chamber pressing pressure, d. one time squeeze , e. oil yield up to 93% , f. dry cake oil residual is slow.