Palm Kernel Oil Pressing Machine - Palm Oil Plant

- Type: palm kernel oil press machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100-650 kg/h

- Voltage: all types

- Key Selling Points: Energy Saving

- Weight: 800 KG

- Dimension (length x width x height): 2000*1210*1700 mm

- Country: nairobi

The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing. Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes.

6YL-130 Palm Kernel Oil Press Machine

- Type: palm oil processing machine

- Production capacity: 1tpd-1000tpd

- Voltage: 220V/380V

- capacity: 40-60kg/ hour

- Weight: 288kg

- Dimension (L*W*H): 1260*1300*850mm

Ⅰ. The 6YL-130 Palm Kernel Oil Press Machine Introduction 1. Screw Oil Press Machine Description. The screw oil press is an oil press that makes full use of the screw driving force to extract oil from the oil to increase the oil output. The structure is simple and the functions are user-friendly. It is suitable for cold pressing and hot pressing.

Palm kernel oil is an edible plant oil extracted from the palm kernel, a by-product of the palm oil mill plant. Our Palm Kernel Oil Press Machine is designed to meet the needs of modern palm kernel oil production with capacities ranging from 10 TPD to 100 TPD. Engineered with precision and innovation, it delivers high-quality oil extraction

palm oil line

- Usage: palm oil

- After-sales Service: 1 Year

- Voltage: 380V

- Press Series: Second

- Press Materials: Sunflower, Soybean, Coconut, Peanut, Mustard

- Appearance: Vertical

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine. Besides, nuts and fibre or press cake will also be discharged as palm oil pressing residues. Palm Oil Pressing Machine (Oil Extraction)

YZYX168P Palm Oil Press Machine

- Type: cooking oil extraction machine

- Production capacity: 1TPD-1000TPD

- Power (W): according to capacity

- Voltage: 380V

- Dimension (L*W*H): various with capacity

- Weight: changed with capacity

YZYX168P automatic temperature control palm oil press is a big capacity model developed by our company to meet market demand and specially for palm oil extraction. The thickness of the cake could be adjusted by adjusting the pressure in the press chamber through the elastic device, so that the palm kernel won’t be crushed easily.

The palm kernel is then milled into small particles, heated, and pressed by the palm kernel oil press. The raw palm oil is purified with a filter press and filled for selling. Our oil pressers are designed with durability, high efficiency, energy-saving features, and reasonable design. They are widely used for all kinds of grain and oil

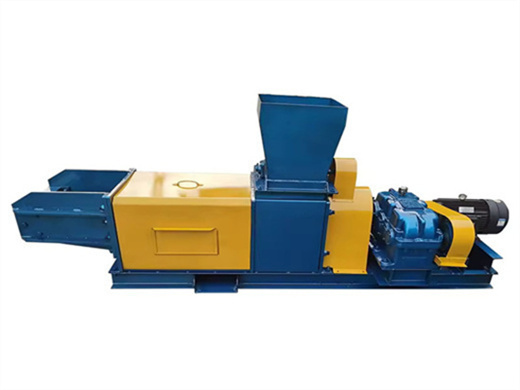

BEST Palm Kernel Crushing Machine | Palm Kernel Processing Plant

- Raw Material: palm

- Voltage: 380v 440v

- Dimension (L*W*H): According to your machine production per day

- Power (W): Capacity

- Weight: Depends on production

- Material: stainless steel

The main machines used in palm kernel oil extraction plant include nut & fiber separating machine, palm kernel crushing machine, cooking machine, palm kernel oil extraction machine (mechanical screw pressing), oil filter press machine, etc. Nut & Fiber Separation: It is also known as palm kernel recovery.

The output of 6YL-95A palm kernel oil press is 200kg/h, and the motor power is 15kw. It is suitable for small oil mill. The 6YL-130A palm kernel oil press capacity is 500kg/h, and the motor power is 22kw. The bigger motor increases the working efficiency of the oil press. And this machine uses thickened and enlarged gears, which are more