Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil processing machine

- Usage/Application: cottonseed

- Production capacity: 60-400 kg/h

- Voltage: Customizable

- Warranty: 1 year, 12 months

- Weight: 1100 KG

- Dimension (L*W*H): 1800*1200*1550 mm

- Country: kenya

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Production capacity: 3.5-4TPD

- Voltage: 220V/380V

- Main components: Gearbox

- Weight: 520 kg

- Dimension (length*width*height): 1650*680*1320

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Cottonseed Oil Extraction Process. Our cottonseed oil extraction plant uses a well-structured process to extract premium oil from cotton seeds. With precise cleaning, dehulling, and solvent extraction, we ensure maximum yield and purity for various industrial and edible applications.

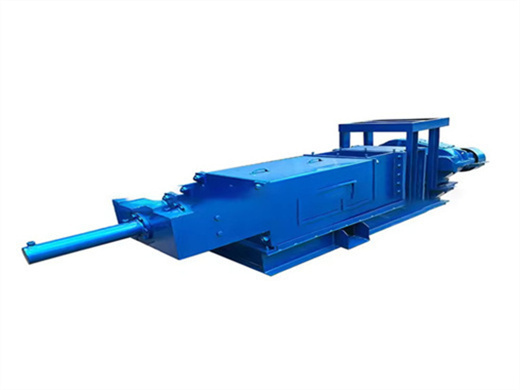

Cotton Seed Processing, Oil Extraction & Refining Plant

- Usage: cottonseed oil

- Production capacity: 10T-3000T/D

- Voltage: 380V

- Weight: According to request cooking extruder machine

- Dimension (L*W*H): 1700*1100* 1600mm

- Power (W): 11KW

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption.

Cottonseed Oil Expeller Manufacturer, Seed Cleaning Machinery

- Type: cooking oil extraction machine

- Main components: PLC, bearing, motor

- Power: NA

- Voltage: NA

- Weight: 6.7 KG

- Dimension (L*W*H): Customized

Established in 2004, Mitsun Engineering is an exporter and manufacturer of engineering machinery such as Oil Expellers, Cottonseed Oil Expeller, Cotton Seed Expeller, Seed Cleaning Machinery. Our company has the capability to supply various types of machines as per the drawings of the clients and their specific requirements.

The percentage of hulls for cotton seed, sunflower seeds and soybean are 45, 25 and 7 percent, respectively. Hulls and shells of oilseeds do not contain a significant amount of oil (less than 1 percent).

Cottonseed Oil Manufacturing Process Flowchart - Oil Expeller

- Raw Material: cottonseed oil

- Production capacity: 2.5-3,500 kg/h

- Dimension (L* W*H ): 48*25*41 cm

- Voltage: 200-240 V, 200-240 v

- Weight: 13 KG

- Main components: motor, pressure vessel, pump

We are your reliable manufacturer of cottonseed oil manufacturing plant. Quality, technology and service are three things that we always focus on as our commitment. Our Best Machinery gathers professional cooking oil processing professors and we can deal with any questions on oil production machinery design, manufacture and oil mill plant

Cotton Seed Processing Plants Posted on May 2, 2013 by admin We offer cottonseed processing plants which includes several stages of processing like delinting, dehulling, hullbeating, meats recovery, cooking and conditioning etc.The cooked meats are subjected to oil recovery by expellers.