The most efficient palm oil processing technologies - Andritz

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Customized: not customized

- After-sales service provided: engineers to repair machinery abroad

- Delivery time: 7~30 days once order confirmed

- Port: Shanghai, Chongqing, Guangzhou, etc

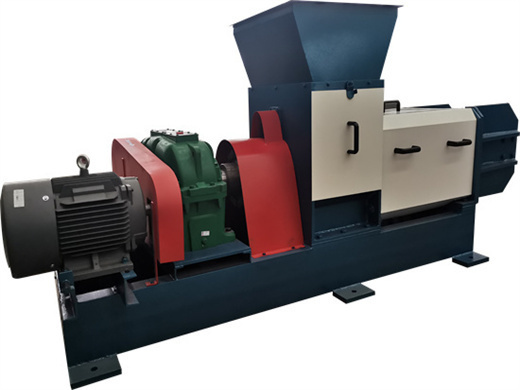

- Name Product: Most popular automatic spiral oil press

- Country: zambia

Palm oil is one of the most important commodities in the world’s oil, fat, and biofuel markets. ANDRITZ is the only supplier that offers decanters, filter presses, screw presses, belt presses, and spray congealers, providing the right solutions to meet the separation needs of palm oil producers and users. Whatever the step in the palm oil

What are the machines used for palm oil processing?

- Type: palm oil processing machine

- Production capacity: 5TPD

- Voltage: 220V/380V

- Main components: PLC

- Weight: 500 kg

- Dimension (length x width x height): 1200*580*1400

As for different palm oil processing capacity, there two kinds of screw palm oil press machine for people to choose, one is screw palm oil press machine, the other is double screw palm oil press machine. Screw palm oil press machine. 6. Oil Clarification Station: for the filtration stage, a vibrating screen, an crude oil clarification tank

Tips: When the filtering cloth absorbs too much impurities, the pressure in the vacuum tank will increase, and the filter paper needs to be replaced in time.Due to the high impurity content of crude palm oil, this type of filter press machine also needs to change the filtering cloth frequently, which is not good for continuous operation.

150KG/H Centrifugal Oil Filter Machine - oil press machine

- Usage: palm oil

- Production capacity: 80-800kg/h-99%

- Voltage: 380V

- Raw material: sesame, olive, soybean, sunflower,

- Weight: 1800KG

- Dimension (L*W*H): 2550*1800*2700( mm)

Supply turnkey palm oil pressing plant and all kinds of quality palm oil machines including palm oil press, palm oil expeller and filter with competitive price. Send an inquiry now and tell us your budget, situation and other requirements. Then we can guide you starting palm oil pressing and refinery business step by step.

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.

Digester and Pressing : VIRIDIS Engineering Sdn Bhd

- Type: cooking oil extraction machine

- Production capacity: 80%-100%

- Dimension (L*W*H): 1200*650 *1850mm

- Voltage: 380V/50HZ, 480V is optional

- Weight: 200 KG

- Main components: Motor

After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities (crude palm oil), and the press cake (fibre and nut). The extracted oil is mixed with fruit particles, water, sand and dirt. The press cake consists of palm fibre and nuts.The remaining fibres and nuts are recovered and dried.

Palm oil mil process of purification: oil purification process to improve palm oil purity. Palm oil mil process of drying: continuous Vacuum drier with the oil out of the water, the water can be reduced to 0.1%. 9.Palm oil mil process of depericarper (splitter): through floating dry processing the fruit core and fibers separated. Fiber

Palm Oil Processing Production Line

- Raw Material: palm

- Production capacity: 200kg/h-2000kg/h-100%

- Dimension (L*W*H): 55* 38*30cm

- Voltage: 220/110V

- Weight: 13 KG

- Warranty: 3 years, 3 years

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

2.4.1 Portable Filter Cart. A portable filter cart is attached to the machine as an additional filtration system. When the system is not working, lubricating oil is added to the filter car and it is added back to the machine after filtering. Portable filter carts are used for hydraulic filtration when a new filter is installed in the machine.