Sunflower Oil Refinery Machine in lesotho

- Type: sunflower oil machine

- Usage/Application: sunflower

- Production capacity: 1t/day-1t/hour

- Voltage: 220V/380V

- Main components: motor, gear

- Weight: 8500 KG

- Dimension (L*W*H): 3800*1240*3400mm

- Country: lesotho

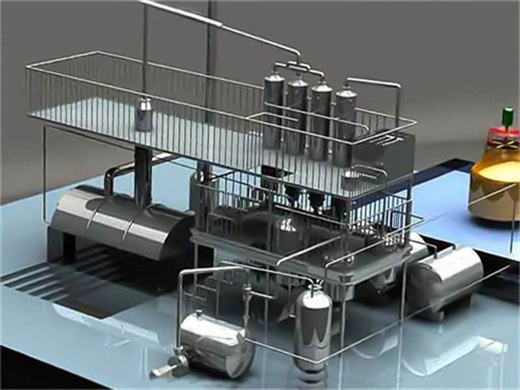

What is an industrial sunflower oil refining machine? An industrial sunflower oil refining machine ( cooking oil refinery equipment) is developed to meet the needs of various edible oil processing plants to refine sunflower seed oil and other kinds of cooking oil. Such equipment can produce fourth-grade oil, third-grade oil, second-grade oil, and first-grade oil. What is the processing

What Are Sunflower Oil Refining Process Techniques?

- Type: sunflower oil processing machine

- Voltage: 220V~380V

- Power (W): 55kw

- Solvent: hexane

- Commercial energy: Electricity

- Dimension (L*W*H): 1200*400*900mm3

Flow Chart - Sunflower Oil Refining Process. Pretreatment: The pretreatment stage involves sedimentation and filtration of the raw sunflower seed crude oil to remove large particles and impurities. Degumming Stage: Soluble impurities in crude sunflower oil not only affect stability of the oil but also the efficiency of oil refining and further

Sunflower oil has a high nutritional value, having 62-70% linoleic acid content (essential fatty acid) but on the other hand this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. Crude sunflower oil, which has reached a certain level of oxidation is difficult to refine. There are two main difficulties: 1.

Sunflower Oil Refining Process Essentials for Optimal Effects

- Usage: sunflower oil

- Production capacity: 10-1500 kg/h

- Voltage: 220 V

- Main components: Motor

- Weight: 35KG

- Dimension (L*W* H): 67*24*42 cm

Sunflower Oil Refining Equipment List; Sunflower oil hydration and degumming equipment: 1. Hydration tank (intermittent, same as alkali refining pot) 2. Vacuum dryer 3. Desolventizer (dedicated to remove residual solvents from leaching branched hairy sunf

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

cooking oil refining plant in lesotho - Complete Oil Processing

- Type: cooking oil extraction machine

- Production capacity: 98%

- Dimension (L*W*H): 1510*440*700mm

- Voltage: 220V/380V /440V

- Weight: 360KG, 360kg

- Warranty: 1 year

Sunflower oil processing involves many process that will decide the equipment and machinery for a sunflower oil processing plant. For small scale sunflower oil processing line, the equipment may be relatively simple and easy to operate. Of course, the investment cost for small scale oil factory is low but the profits is considerable. If you are interested in the sunflower oil processing, please contact us for more detailed information!

Download scientific diagram | Extracting and refining steps of sunflower oil. from publication: Effects of refining process on sunflower oil minor components: A review | Sunflower oil is well

Sunflower oil refining machine from crude oil to first grade

- Raw Material: sunflower

- Production capacity: 3.5-50 kg/h

- Dimension (L*W*H): 360*155*310 mm

- Voltage: 220 V

- Weight: 7 KG

- Main components: Motor

Refined Sunflower Seed Oil sunflower seed oil refining process. Sunflower oil refining methods can be roughly divided into the mechanical method, chemical method, and physicochemical method. The operation of the sunflower oil refining machine is divided into the following four steps. 1.

The production process of sunflower oil is as follows: sunflower seeds screening - cleaning impurities - hulling - crushing - steaming - pressing - solvent extraction - filtration - refining - sunflower oil. First, we need to screen and clean sunflower seeds to remove impurities. Secondly, shell and crush the sunflower seeds with a sheller and crusher. Third, the crushed sunflower seeds will be steamed and fried to reduce the impact caused by moisture. Fourth, the steamed and fried sunflower seeds are pressed to form gross oil in a sunflower oil press. Fifth, the sunflower oil is extracted with solvents and filtered. Finally, the filtered sunflower oil is refined to form edible oil.