edible oil refinery mill manufacturers in rwanda

- Type: sunflower oil refinery plant

- Usage/Application: sunflower

- Production capacity: 50T~150TPD

- Voltage: 220V/380V

- Weight: 1050 KG

- Dimension (L*W*H) : 1610x615x1260mm

- Power (W) : According to capacity

- Country: rwanda

MeTL Group, through East Coast Oils and Fats, boasts 60% of the total market share in edible oil sales from the plant’s 45,000 metric tons production monthly. East Coast Oils and Fats currently has three oil refineries capable of refining 2400 metric tons per day (over 70,000 metric tons per month), a manufacturing line of soaps with an

Sunflower Oil Manufacturing Plant Report 2025 | Setup Cost

- Type: sunflower oil refinery machine

- Certification: ISO, CE, BV

- Warranty: 1 year

- Solvent consumption: less than 2 kg/t

- Energy consumption: no more than 15 KWh/T

- Residual oil in flour: less than 1%

IMARC Group’s report titled “Sunflower Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a sunflower oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as

All kinds of sunflower oil extraction machine for sale with lowest possible price and premium quality, supplied by ABC Machinery - one of the BEST oil machine manufacturers. With great reputaions in seed oil making field, we can offer the most suitable solution for both small and full scale vegetable oil producing business. You can trust both the machinery quality and after-services we offered.

automatic sunflower oil refining line in rwanda

- Usage: sunflower oil

- Voltage: 380 V

- Power (W): 40 KW

- material: 304# stainless steel

- Dimension (L*W*H): 10680*840*1750

- Weight: 8 tons

Automatic Sunflower Oil Refinery Plant in rwanda. MeTL Group, through East Coast Oils and Fats, boasts 60% of the total market share in edible oil sales from the plant’s 45,000 metric tons production monthly.

The sunflower oil machine provided by ABC Machinery has many favorable features. It is compact in design, efficient in oil pressing, convenient in maintenance and operation. Most importantly, it can be also used to process a very wide range of oil-bearing seeds and oil-rich plants, such as peanut/groundnut, palm kernel, cottonseed, soybeans, copra, south africai seeds, corn germ and more.

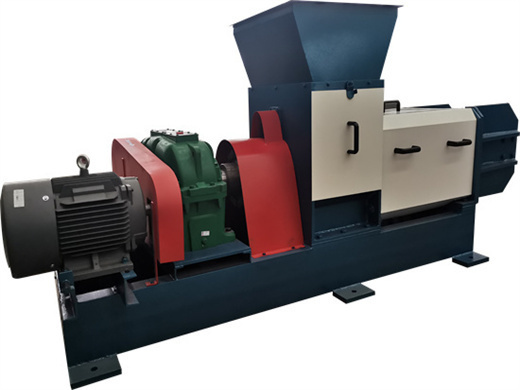

sunflower cotton seed oil refinery machine in rwanda

- Type: cooking oil refining machine

- Production capacity: 200TPD

- Dimension (L*W*H ): 1200*400*900mm3

- Voltage: 220V/380V

- Weight: 1000kg

- Heating system: Heat-conducting oil

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

We design and develop complete integrated refinery plant and system specially for sunflower oil. Sunflower oil is considered to be one of the most stable oils for frying. The demand for oils with a lower degree of unsaturation than those of traditional oils has significantly increased the availability of oils of high thermostability.

Rajham Refineries

- Raw Material: sunflower

- Production capacity: 100kg/h-1000kg/h

- Dimension (L*W*H): 450*165* 285mm

- Voltage: 220V

- Weight: 11kg

- Main components: Motor

Rajham Refineries was established in the year 1993. We are a leading manufacturer of Refined Sunflower Oil, Refined Groundnut Oil, Ground Nut Oil and Refined Cotton Oil. Our primary focus is best-in-market Quality and customer satisfaction – we have the state-of-the-art refinery equipment and vastly experienced manpower to ensure the same.

The production process of sunflower oil is as follows: sunflower seeds screening - cleaning impurities - hulling - crushing - steaming - pressing - solvent extraction - filtration - refining - sunflower oil. First, we need to screen and clean sunflower seeds to remove impurities. Secondly, shell and crush the sunflower seeds with a sheller and crusher. Third, the crushed sunflower seeds will be steamed and fried to reduce the impact caused by moisture. Fourth, the steamed and fried sunflower seeds are pressed to form gross oil in a sunflower oil press. Fifth, the sunflower oil is extracted with solvents and filtered. Finally, the filtered sunflower oil is refined to form edible oil.