sunflower oil extraction line

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 3-4 t/24h Soybean oil machine

- Voltage: 220V/380V Soybean oil machine price

- Main components: Others

- Weight: 700KG

- Dimension ( L*W*H): 1480*630*1570mm

- Country: pakistan

100TPD sunflower seed cake extraction & 30TPD sunflower oil refining project is designed and manufactured by China Huatai Machinery. From process & drawing design,equipment manufacturing,equipment inspection to other related section, Huatai team provides the qualified and satisfied equipment according to high standard and strict requirements.

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

- Type: sunflower oil processing machine

- Production capacity: 3 tons/day

- Dimension (L*W*H): 7.16*2.24*4.66 ft

- Main components warranty: Others

- Warranty: One year warranty against manufacturing defect.

- Weight: 0 KG

Steps Involved in Sunflower Oil Extraction Process. The sunflower oil extraction process involves several steps, including cleaning, dehulling, cooking, pressing, and refining. Cleaning involves removing any foreign material and impurities from the seeds. The dehulling process helps to remove the outer shell of the seed to access the oil-rich

100TPD Sunflower Seed Cake Solvent Extraction & 30TPD Oil Refining Equipment for Uzbekistan Customer Read More 5TPD Edible Oil Refining Line to Myanmar in Loading

What is the difference between pressing and solvent

- Usage: sunflower oil

- Production capacity: Depends

- Voltage: 220V/380V

- Dimension (L*W*H): according to capacity

- Weight: according to capacity

- Power (W): according to capacity

Solvent extraction: While it yields more sunflower oil, it may result in sunflower oil with trace solvents and lower sensory qualities. Additional refining steps are usually necessary. 4. Cost Considerations: This is probably one of the most important difference between pressing and solvent extraction of sunflower oil for customers.

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

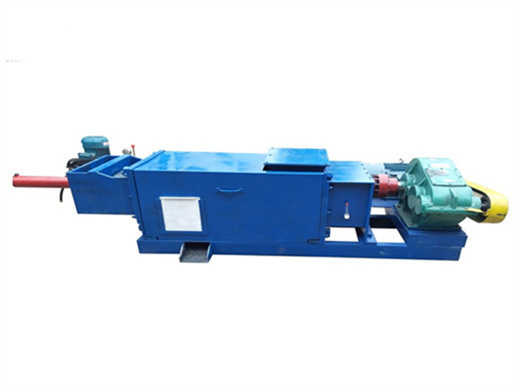

Sunflower oil processing machine - edible oil extraction machine

- Type: cooking oil extraction machine

- Production capacity: 100% cooking mixer machine

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W* H): Depends on its capacity

- Power (W): Depends on its capacity

After sunflower oil solvent extraction plant , the residual oil rate in sunflower cake is less than 1%. Daily treatment : 30T, 50T, 80T,100T,150T, 200T, 300T, 450T, 600T, 800T. ..2000T ,As your requirement. Sunflower oil solvent extraction plant 3D animation Sunflower oil solvent extraction process of sunflower oil processing machine:

Edible oil 30TPD Most popular sunflower oil press plant is utilizing the principle of Cotton Seed Oil Extraction Machine can be dissolved in oil fat to extract oil out, then we can get the mixture of theCotton Seed Oil Extraction Machine ,Business listings of Cotton Seed Oil Extraction Machine manufacturers, suppliers and exporters in India along with their contact details & address.

Dinter 30TPD refined sunflower cooking oil plant Manufacturer

- Raw Material: sunflower

- Production capacity: standard

- Power (W): 7. 5 KW

- Voltage: 380V

- Weight: standard

- Dimension: 1950x1300x1900

Dinter 30TPD refined sunflower cooking oil plant is extracted from the fruits of the oil palm trees (or some times referred to as oil palms). These trees, which originated in Expeller Pressed Machine, Process of Palm Oil Production Line. Palm oil is extracted from the fruits of the oil palm trees (or some times referred to as oil palms).

In the whole sunflower oil production line, sunflower seeds should be shelled, cleaned, cooked, and pressed. a sunflower oil solvent extraction plant is used to achieve a high oil yield. Through the sunflower oil solvent extraction process, the oil residue will be less than 1%, and the meal will be more suitable for animal feed.