Sunflower Oil Production Plant Process Flowchart - GOYUM GROUP

- Type: sunflower oil plant

- Usage/Application: sunflower

- Product color: customers' choice

- Voltage: 220/380 Or other

- Steam consumption: ≤ 280 KG/T (0.8 MPa)

- Production capacity: 20-2000TPD

- Residual oil in flour: ≤ 1%

- Country: cameroon

Wide application of Sunflower Oil Production. Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system

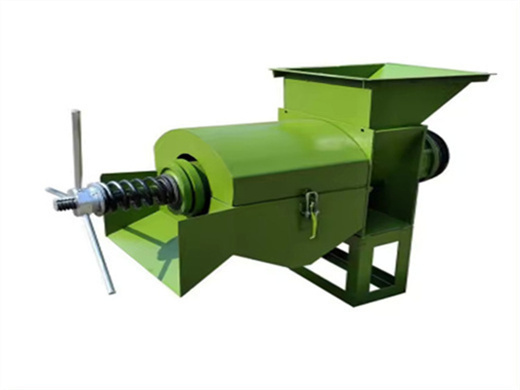

simple operation sunflower oil extraction plant in cameroon

- Type: sunflower oil processing machine

- Weight (KG): 1000

- Machine type: Drilling rig

- Product Model: JG/S78-105

- Processing type: Forging

- Material: Carbide

Sunflower Seed Preparation and Oil Extraction. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

The purpose of pressing is to extract sunflower seed oil by mechanical pressing while providing pressing cakes for extraction plant. Main processes include: Seed Cleaning , Stone Removing& Weighing, Peeling, Flaking, Cooking, Pressing, Oil Residue Separation, Sunflower Seed Cake Extraction

Sunflower Oil Production Line for Sunflower Oil Plant to

- Usage: sunflower oil

- Product Type: Nut and Seed Oil

- Processing Type: Refined

- volume, l: 1,2,3,4.5, 5, 10

- Grade: Superior

- Packaging: Bulk, Bottling

Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body,

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

Sunflower seed oil production manufacturing process analysis

- Type: cooking oil extraction machine

- Production capacity: 100-6000kg/h

- Dimension (L*W*H): 175*375 *300 mm

- Voltage: 220V/110V

- Weight: 1000 kg

- Main components: Motor

Sunflower oil production contains the following manufacturing processes:1.Sunflower seeds cleaning,dehulling,flaking,cooking,pressing;2.Using solvent to extract crude sunflower oil from sunflower seeds;3.Refining the crude sunflower oil into refined oil.

Watch the step-by-step journey of sunflower oil production, starting with harvesting the sunflower seeds, followed by cleaning, crushing, pressing, and finally the extraction process that creates

the price of sunflower oil processing plant in Cameroon

- Raw Material: sunflower

- Production capacity: NA

- Dimension (L*W*H): NA

- Voltage: NA

- Weight: 600 KG

- Warranty: 2 years

SUNFLOWER SEED PROCESSING 15 2.1 Sunflower seed processing into oil 15 2.2 Conversion factors from raw material 18 2.3 Oil composition and physical properties 19 How much does it cost to build a sunflower oil processing plant?

The final oil residue can be less than 1%. It is usually suitable for large capacity sunflower oil production line above 20tpd. Sunflower oil solvent extraction → Wet meal desolventizing and drying → Miscella oil evaporation and stripping → Solvent condensing and cooling. 3. Sunflower Oil Refinery Plant: Sunflower oil refinery plant is to