Sunflower Oil: How Easy Is It to Make? - The Cooking Facts

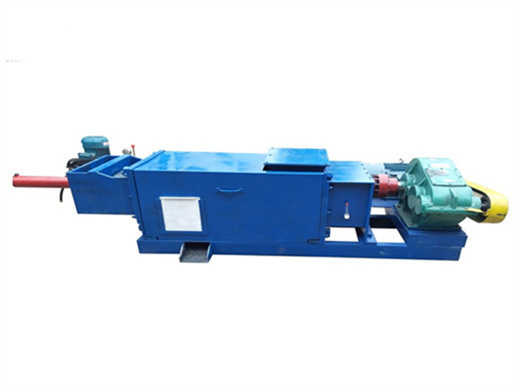

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 450kg/h

- Voltage: 380v,50hz,3p

- Main components: motor, gearbox

- Weight: 950 KG

- Dimension (L*W*H): 2200x640x870mm

- Country: nairobi

The sunflower oil extraction process can vary in duration depending on the method used and the quantity of seeds. If you are using a home oil press, the mechanical extraction typically takes around 30 minutes to an hour for a small batch.

Different extraction methods of sunflower oil: pressing

- Type: sunflower oil processing machine

- Production capacity: 200-300 kg/h

- Voltage: 380v

- Main components: gear, bearing

- Weight: 260 KG

- Dimension (length x width x height): 1650x1150x1750

Compared with the sunflower oil pressing method, the sunflower oil solvent extraction method has a higher oil yield but also higher cost. In addition, the sunflower oil solvent extraction method requires the use of chemical solvents, which have some impact on the environment, so environmental protection issues need to be considered.

Steps Involved in Sunflower Oil Extraction Process. The sunflower oil extraction process involves several steps, including cleaning, dehulling, cooking, pressing, and refining. Cleaning involves removing any foreign material and impurities from the seeds. The dehulling process helps to remove the outer shell of the seed to access the oil-rich

SMALL-SCALE SUNFLOWER OIL EXPELLING TECHNOLOGY

- Usage: sunflower oil

- Production capacity: 5TPD

- Voltage: 220V/50HZ

- Main components: Motor

- Weight: 63 KG

- Dimension (L*W*H): 800*400 *1000 mm

conditioners, oil expeller, filtration units / pumps, storage tanks Oil refining costs 1. Small-scale expelling Oil expellers with the capacity 50 to 300 kg seed per hour are regarded as small-scale. These are the typical on-farm and non-industrial units presently supplied to SMME’s. Typical examples are the Reinartz expeller AP VII (SLIDE).

(Read more about Small Scale Sunflower Seed Dehuller >>) Seed Grinding; In this step, the de-hulled sunflower seeds are grounded using mechanized rollers or hammer mills to make a meal that is later heated for oil extraction. The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction

How Is Oil Extracted From Sunflower Seeds? - LEAFtv

- Type: cooking oil extraction machine

- Automatic grade: Semi-automatic

- Production capacity: 1-500T/D

- Dimension (L*W*H):1910*550*765 mm

- Power (W): 7.5kw

- Voltage: 220V /380V

The oil must be extracted to separate it from the solids using one of several processes. Three types of sunflower oil produced for cooking applications, which vary in oleic levels, are: NuSun, linoleic and high oleic. Oil-seed-type sunflower seeds are used for oil production rather than for common snack seeds.

Mid-Oleic Sunflower Oil: A balanced option that contains a moderate level of both monounsaturated and polyunsaturated fats. This versatility allows it to be used in a variety of culinary applications, from sautéing vegetables to baking pastries. Extraction Process. The extraction of sunflower oil typically involves several steps.

A Step-by-Step Guide on How Sunflower Oil is Made

- Raw Material: sunflower

- Voltage: No

- Weight: 122.5 KG

- Dimension (L*W*H): 1*1*1

- Warranty: 6 months

- Main components: Others, oil press parts

Solvent extraction is the part of the sunflower oil making process in which almost every last drop of oil is extracted from the sunflower seeds. Hexane is the most widely used solvent for this. The process begins with the pouring of hexane over the leftover cake from expeller pressing.

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.