oil solvent extraction manufacturers in ethiopia

- Type: sunflower oil press

- Usage/Application: sunflower

- Production capacity: 50 liters/day

- Voltage: 220 volts

- Main components warranty: Not available

- Weight: 750 KG

- Dimension (length*width*height): 6 x 3.25 x 5.5 ft

- Country: ethiopia

Sunflower oil manufacturing is a complex process involving various stages. The quality of the oil depends on the oilseed quality as well as the quality of sunflower oil processing machine. Sunflower seeds need to be pre-treated prior to oil extraction process to separate out impurities. This is followed by oil pressing and solvent extraction.

High-Quality Sunflower Oil Press Machine | Efficient & Cost

- Type: sunflower oil processing machine

- Structure: Horizontal

- Voltage: 110/220V

- Press per hour: 5-7 kg

- Power: 880W

- Screw size: 252 mm

Our product line covers a full set of sunflower oil processing equipment from raw material pretreatment, pressing, leaching, refining to filling. The use of advanced low-temperature cold pressing technology and environmentally friendly solvent leaching system effectively retains the nutrients and natural flavor of sunflower oil while reducing

- Removes the outer husk or shell of the sunflower seed. - This step increases oil yield and ensures a higher quality of oil. 3. Oil Expeller/Press: - Mechanically presses the sunflower seeds to extract the oil. - Can be either a cold press (preserves nutrients but has a lower yield) or hot press (higher yield but may lose some nutritional

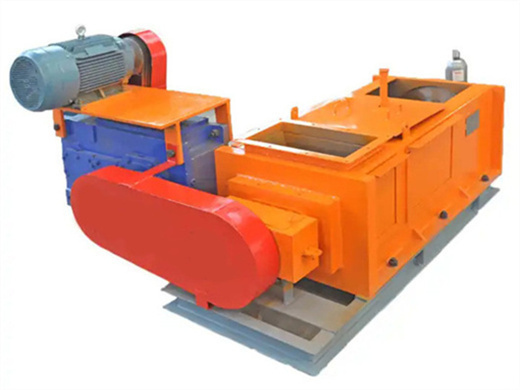

sunflower seeds oil production line – oil press in ethiopia

- Usage: sunflower oil

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 18.5 KW

Sunflower Oil Production Line - Seed Oil Press. More specifically, the operation steps and equipment for processing sunflower oil are as follows: 1. Sunflower Seeds Selecting 2. Shelling & Crushing 3.Sunflower Seed Flaking 4.Seed Embryo Steaming 5.Pre-squeezing & Leaching 6. Crude Oil Refining

Explore our extensive range of sunflower oil machines including pressing, milling, and extraction equipment to boost your production efficiency. Contact us for tailored solutions!

Sunflower Oil Production Plant Process Flowchart - GOYUM GROUP

- Type: cooking oil extraction machine

- Production capacity: 10TPD

- Voltage: 220V/380V

- Main components: Pump

- Weight: 580 KG

- Dimension (L*W*H): 700*500* 1000 mm

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

Sunflower seed oil is extracted from oil-type sunflower seed by the mechanical pre-pressing method with subsequent hexane extraction of the remaining oil in the meal. To be specific, oil-used sunflower seeds contain 45%~60% of the oil which is suitable for the pre-pressing and leaching method: In the 1 st , the raw seeds are pre-squeezed by

Sunflower Oil Production Line for Sunflower Oil Plant to

- Raw Material: sunflower

- Production capacity: 100-1000 kg/h

- Dimension (L*W*H): 2900*1850*3640

- Voltage: 380

- Weight: 5500KG

- Main components: Engine

The artificial cream obtained with sunflower oil has excellent taste and high unsaturated fatty acid content. In the food industry, sunflower oil is also used to make fried fast food, such as potato chips and corn chips. The sunflower oil cake which obtained after squeezing contains 30%~36% of protein and 8%~11% of fat.

The sunflower seed is the fruit of the sunflower (Helianthus annuus). Botanically speaking, it is more properly referred to as an achene. When dehulled, the edible remainder is called the sunflower kernel or heart.The original sunflower oil (linoleic sunflower oil) is high in polyunsaturated fatty acids (about 68% linoleic acid) and low in saturated fats, such aspalmitic acid and stearic acid