Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: sunflower oil processing machine

- Usage/Application: sunflower

- Production capacity: 6-80t/24h

- Voltage: 220V/380V

- Function: Sesame Oil Machine

- Weight: 1400kg

- Dimension (L*W*H): 2200*1650*1750mm

- Country: nairobi

Bleaching. This is one the important stage in total refining process. Where the oil is heated to 100°C to 105°C and mixed with Bleaching earth chemical ( Acid Activated Clay) and also activated carbon in a vessel under vacuum at 70 mmHg where the stirring continues for specific designated time and then filtered the oil to remove the clay and carbon.

Efficient Sunflower Oil Manufacturing Machines | Enhance

- Type: sunflower oil refinery machine

- Production capacity: Depends

- Voltage: 220V/380V

- Dimension (L*W*H): according to capacity

- Weight: according to capacity

- Power (W): according to capacity

A sunflower oil manufacturing machine is designed to process sunflower seeds into oil through a series of steps that involve cleaning, pressing, and refining. These machines are used in small-scale operations, medium-sized businesses, and large industrial facilities to produce edible sunflower oil efficiently.

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

Sunflower Oil Making Machines for Sale

- Usage: sunflower oil

- Production capacity: 1-500T/D

- Voltage: 380V-415V

- Weight: depends on the oil machine mode

- Dimension (L*W*H): depends on the oil machine mode

- Power (W) : depends on the oil machine mode

Read more about sunflower o il refining machine for further processing of crude sunflower oil >> Establish Complete Set Sunflower Oil Processing Plant. Sunflower oil was first used for cooking a couple of centuries ago and is still the number one vegetable oil. Domestic and international demand keep increasing over the decades.

4. Use sunflower oil pre-pressing machine to obtain a part of sunflower oil form sunflower seeds. Sunflower oil solvent extraction plant: Machines used in sunflower oil solvent extraction plant. 1. Sunflower cakes are sent into extractor, then soaked in solvent, at last the mixed oil will flow out of the extractor. 2.

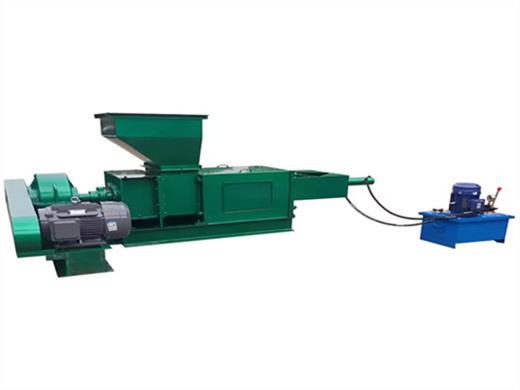

Sunflower oil manufacturing process - Edible Oil Expeller

- Type: cooking oil refining machine

- Production capacity: 9-11 t/24h

- Dimension (L*W*H): 2010 *690*1430

- Voltage: 380v/50hz

- Weight: 806 KG

- Main components: gear, bearing, motor, gearbox

1. Sunflower oil pre-press process Sunflower→ Magnetic seperating( Metal impurities)→ cleaning→ husking→ flaking roll→ Cooking→ pressing workshop First, use magnetic separator, de-stonner and vibrate cleaning sieve to remove metals, small stones, impurities from sunflower raw seeds. Second, use husking machine to remove husks, separating screen to separate husk and sunflower kernel

Our product line covers a full set of sunflower oil processing equipment from raw material pretreatment, pressing, leaching, refining to filling. The use of advanced low-temperature cold pressing technology and environmentally friendly solvent leaching system effectively retains the nutrients and natural flavor of sunflower oil while reducing

Sunflower oil refining machine from crude oil to first grade

- Raw Material: sunflower

- Production capacity:7TPD

- Dimension (L*W*H): 1718*1450*1910mm

- Voltage: 380V/50HZ

- Weight: 973 KG

- Main components: Motor, gear, loops and spirals

Refined Sunflower Seed Oil sunflower seed oil refining process. Sunflower oil refining methods can be roughly divided into the mechanical method, chemical method, and physicochemical method. The operation of the sunflower oil refining machine is divided into the following four steps. 1.

We provide high quality Sunflower Oil Production Machine, best price edible oil processing plant equipment supplier 100TPD full continuous soybean oil refining