Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil processing plant

- Usage/Application: sunflower

- Production capacity: 45 kg per hour

- Voltage: 220-240 volts

- Warranty: 2 years

- Weight: 67 KG

- Dimension (L*W*H)): 840 *240 *540 mm

- Country: uganda

Cost of Sunflower oil extraction machine: Cost of automatic Sunflower oil extraction machine approximately, Rs 1.45 Lakh/Piece. Benefits of Sunflower oil. May enhance oral health. Sunflower oil is extremely useful for oil pulling. Sunflower oil reduces plaque-related gingivitis.

How Is Sunflower Oil Made? (The Step-by-Step Process)

- Type: sunflower oil processing machine

- Production capacity: 50-500kg/h

- Voltage: 220V/380V/as your request

- Key selling points: Multifunctional

- Weight: 950 KG

- Dimension (L*W*H): 900*1000*1400 mm

Filtering and Processing Sunflower Oil. Once the sunflower oil is extracted from the seeds, it needs to be filtered and processed to remove any impurities. This is done to ensure the oil is high-quality and nutritious. The process of filtering and processing sunflower oil is relatively straightforward.

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

Processing Edible Oils - Penn State Extension

- Usage: sunflower oil

- Press Series: First

- Customized: Customized

- Automatic Grade: Automatic

- Item: Screw Oil Press Machine

- Power: 5.5kw

In a typical edible oil processing plant, oil is extracted from the seed first using mechanical extraction (expeller press) followed by chemical extraction (hexane extraction). By using both methods, less than 1% of the oil is left in the meal that is produced. The majority of this meal is sold for use in animal feed rations. Components of

Factors Affecting Sunflower Oil Extraction Yield. The yield of sunflower oil extraction can be affected by various factors, including seed quality, processing conditions, and extraction methods. The quality of the seeds used for extraction is a crucial factor that can significantly impact the yield of the oil.

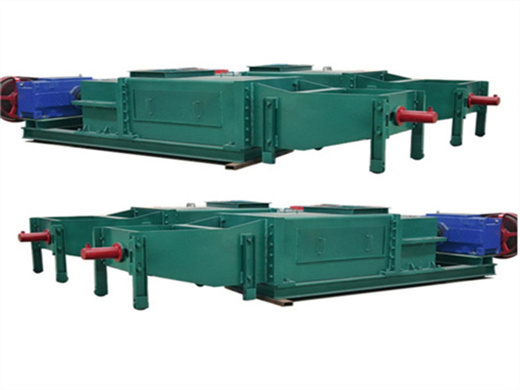

Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: cooking oil extraction machine

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 140*100*150 cm

- Voltage: 220V/380V

- Weight: 680 kg

- Warranty: 3 years

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

Please send us price quotation for oil press processing plant with break down on prices per components of the oil processing machine and it’s equipment. It must be able to produce oil between 15 to 20 tons per day. Thank you so much. Please send price quotation CIF Mombasa Kenya by sea to Uganda East Africa as final destination.

What are the steps involved in the process of sunflower oil

- Raw Material: sunflower

- Weight: 100 kg

- Oil type: cooking oil

- Main components: motor, gear

- Product power: 600~1500W

- Voltage: 110V/220V

Sunflower seed oil is a nutritious, easily digestible and cholesterol-free vegetable oil that is becoming increasingly popular. However, to produce high-quality sunflower seed oil, a certain processing process needs to be followed. Below, I will introduce the steps involved in the process of sunflower oil processing. Selection of raw materials

Sunflower oil production contains the following manufacturing processes:1.Sunflower seeds cleaning,dehulling,flaking,cooking,pressing;2.Using solvent to extract crude sunflower oil from sunflower seeds;3.Refining the crude sunflower oil into refined oil.