300kg per hour virgin screw sunflower oil press machine in zimbabwe

- Type: sunflower oil machine

- Usage/Application: sunflower

- Production capacity: 100%

- Voltage: 220V/380V or match with local voltage

- Weight: 1300kg

- Dimension (L*W*H): 2050*1350*2000mm

- Power (W): 22 KW

- Country: zimbabwe

If you want to start a sunflower oil business, but don't have any experience. Welcome to our column focused on unlocking the whole sunflower oil processing technology. In this column, we will delve deeper into the world of sunflower oil production, exploring its machines, techniques, and market trends and unveil the insider tips and tricks of sunflower oil processing, sharing valuable insights to enhance your production efficiency and ensure product excellence. Be sure not to miss out on this valuable resource!

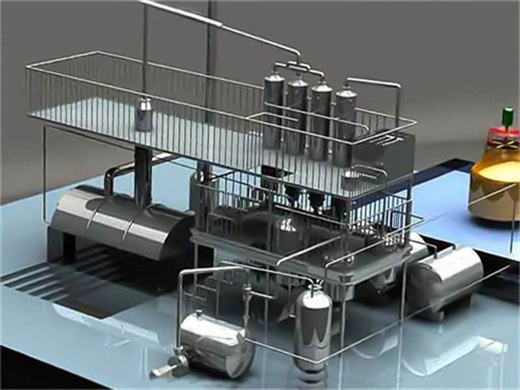

Sunflower Oil Production Line

- Type: sunflower oil processing machine

- Production capacity: 10-12T/24H

- Voltage: 220v/380v

- Weight: 1700kg

- Dimension (L*W* H): 2350*840*1850mm

- Power: 15kw

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

We offer two kinds of single oil press machine for sunflower oil production: Conventional Screw type Sunflower Oil Press; Multifunction Oil Press (equipped with oil filtering device) Sunflower Oil Pressing Machine Spare Parts. Both these two types of oil processing equipment are suitable for make sunflower seed oil. The price of multifunction

Efficient Sunflower Oil Production Machines - Enhance Oil

- Usage: sunflower oil

- Production capacity: 100TPD

- Voltage: 230-380-430

- Weight: 30 tons

- Dimension (L *W*H): 20m*16m*15m

- Power(W): 40kw/h

4. Oil Filtration Machine: - Filters the oil to remove solid particles, impurities, and seed residue. - Produces clear, high-quality sunflower oil suitable for consumption or further processing. 5. Oil Refinery Machine (optional): - Used to refine crude sunflower oil to remove impurities like free fatty acids, phospholipids, and unwanted odors.

sunflower oil process production. As we can see, the sunflower oil production process mainly includes five steps, including cleaning, hulling, flaking, cooking, pressing. And each step is equipped with advanced sunflower oil processing machine. In the following, I will make a detailed introduction about how is sunflower oil processed and the

Screw Sunflower Oil Making Machine for Cost-Effective

- Type: cooking oil extraction machine

- Production capacity: 98%-100%

- Power (W): 22kw

- Voltage: 380V/50HZ

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Weight: 10 tons

Sunflower Oil Making Machine Types and Price. In order to better meet customers' sunflower oil processing requirements, we develops three types of sunflower oil making machines for your choice. Small Sunflower Oil Making Machine. Single Screw Oil Making Machine; Automatic Oil Making Machine with Filters (Air Pressure or Vacuum Filter) Auto

A sunflower oil manufacturing machine is designed to process sunflower seeds into oil through a series of steps that involve cleaning, pressing, and refining. These machines are used in small-scale operations, medium-sized businesses, and large industrial facilities to produce edible sunflower oil efficiently.

What machines are used in the sunflower oil production

- Raw Material: sunflower

- Production capacity: 10T-5000TPD

- Power (W ): 10kw-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2500mm*2000mm*3000mm

- Weight: 2T-20T

Therefore, there will be 5 machines need to be equipped: cleaning machine, husking machine, flaking machine, cooking machine,husking machine, pressing machine filtering machine. Next, I will introduce you the sunflower oil processing steps in view of the sunflower oil production process flow accordingly.

A sunflower oil making machine is used to extract oil from sunflower seeds, designed for small-scale, medium, and large-scale production. The machine is essential in the edible oil industry and has applications in both home-based setups and industrial production plants. It automates the oil extraction process, ensuring efficient, high-quality