Sunflower seed oil production manufacturing process analysis

- Type: sunflower oil refinery machine

- Usage/Application: sunflower

- Voltage: 220V, 380V

- Power: 2.2KW

- Supplier Taste, smell: has the inherent taste and smell of oil, no smell

- Weight: According to processing capacity

- Dimension (L*W*H): Our engineer will design it according to your capacity

- Country: nairobi

Using solvent to extract crude sunflower oil from sunflower seeds; 3. Refining the crude sunflower oil into refined sunflower oil; 4. Sunflower oil packing and filling. Next, I will explain it for you one by one. Sunflower oil processing flow chart: Sunflower seed oil production manufacturing process flow chart

Extracting and refining steps of sunflower oil. | Download

- Type: sunflower oil refinery machine

- Production capacity: 10-3000tpd

- Voltage: 380v

- Main components: motor, pressure vessel, pump, gear, motor, gearbox

- Weight: 5000 KG

- Dimension (L*W*H): See the detailed information

Download scientific diagram | Extracting and refining steps of sunflower oil. from publication: Effects of refining process on sunflower oil minor components: A review | Sunflower oil is well

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

Sunflower Oil Production Plant Process Flowchart - GOYUM GROUP

- Usage: sunflower oil

- Production capacity: 98%-100%

- Voltage: 380V/50HZ

- Weight: 10 tons

- Dimension (L *W*H): 48m*12M*15M(30TPD)

- Power (W): 22kw

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

Flow Chart - Sunflower Oil Refining Process Pretreatment: The pretreatment stage involves sedimentation and filtration of the raw sunflower seed crude oil to remove large particles and impurities. Degumming Stage: Soluble impurities in crude sunflower oil not only affect stability of the oil but also the efficiency of oil refining and further

Sunflower seed oil production manufacturing process analysis

- Type: cooking oil refining machine

- Production capacity: 20-500T/D

- Power (W): 100kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): Depends on capacity

- Weight: Depends on capacity

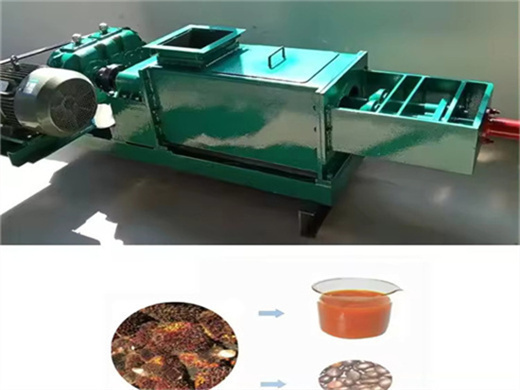

Sunflower seed oil production contains the following manufacturing processes: 1. Sunflower seeds cleaning, dehulling, flaking, cooking, pressing; 2. Using solvent to extract crude sunflower oil from sunflower seeds; 3. Refining the crude sunflower oil into refined sunflower oil; 4. Sunflower oil packing and filling.

The sunflower oil refining process consists of 5 essential steps: degumming, deacidification, decolorization, deodorization and dewaxing process, each with a specific purpose and parameters. Sunflower Oil Refining Plant Process Flow Diagram for Reference

Process flowchart of sunflower oil. | Download Scientific Diagram

- Raw Material: sunflower

- Voltage: 220 V/380 V

- Dimension (L*W*H)): 2000x1400x1850mm

- Power (W): 18.5 KW

- Weight: 15TONS

- Certification: ISO CE BV SGS

Download scientific diagram | Process flowchart of sunflower oil. from publication: The state of the art of food ingredients’ naturalness evaluation: A review of proposed approaches and their

Sunflower oil is extracting from oilseed sunflower, which contains 66% linoleic acid and low cholesterol, so is called 21st century "healthy nutrition oil". The sunflower oil production process in video is physical pressing method, very healthy. Sunflower oil production process flow chart: Sunflower oil production process flow chart