Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: sunflower oil machine

- Usage/Application: sunflower

- Voltage: 380 V/50 HZ

- Power (W): 15 KW

- Raw material: rice bran, almond

- Weight: 1200kg

- Dimension (length x width x height): 1700*1100*1600mm

- Country: indonesia

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

What Are the Primary Steps Involved in Refining Sunflower Oil?

- Type: sunflower oil refinery machine

- Mainly suit for: sunflower, soybean, peanut

- Capacity: 1t-100t/D

- training: our engineer's response to train your staff

- Installation plan: We can provide you

- Installation of equipment: our engineer can come to the service of your country

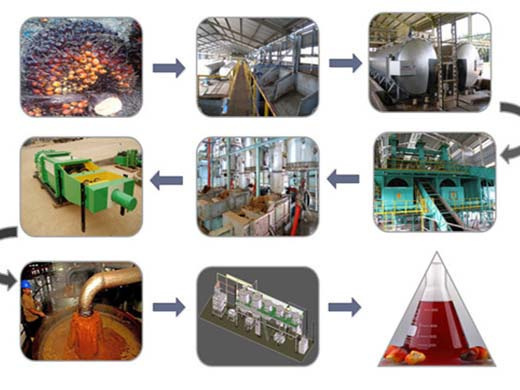

The process of refining sunflower oil starts with using crude sunflower oil as raw material, and finally obtains refined finished oil after a series of processing steps.

Find here 5 TPD sunflower oil refining line cons manufacturers, suppliers & exporters in china. Get contact details & address of companies manufacturing and supplying Solvent Extraction Line across Expeller Pressed Machine. Find here 5 TPD sunflower oil refining line cons manufacturers, suppliers & exporters in china.

PHYSICAL REFINING OF SUNFLOWER OIL

- Usage: sunflower oil

- Supply Type: OEM/ODM

- Product Purity: 100% pure natural cold pressed or refined

- Raw material: Vegetable seeds

- Function: Health care Moisturizing Lose weight

- Appearance: Pale yellow to golden yellow

Sunflower oil has a high nutritional value, having 62-70% linoleic acid content (essential fatty acid) but on the other hand this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. Crude sunflower oil, which has reached a certain level of oxidation is difficult to refine. There are two main difficulties: 1.

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Sunflower oil manufacturing process - Edible Oil Expeller

- Type: cooking oil refining machine

- Production capacity: cook dryer

- Power (W): according to capacity

- Voltage: 220v, 380v, 440v

- Dimension (L*W*H): 430*230*350

- Weight: 1050 KG

1. Sunflower oil pre-press process Sunflower→ Magnetic seperating( Metal impurities)→ cleaning→ husking→ flaking roll→ Cooking→ pressing workshop First, use magnetic separator, de-stonner and vibrate cleaning sieve to remove metals, small stones, impurities from sunflower raw seeds. Second, use husking machine to remove husks, separating screen to separate husk and sunflower kernel

Precision Sunflower Oil Refining Machine Solutions. On the basis of having a reliable sunflower seed refinery process, the choice of edible oil refining line is crucial because it directly affects the quality of final sunflower seed oil. The following table shows the equipment used in sunflower oil refining process, including small batch

Sunflower oil refining machine from crude oil to first grade

- Raw Material: sunflower

- Voltage: 380 V/50 HZ

- Dimension (length x width x height): 1700*1100*1600mm

- Power (W): 15 KW

- Weight: 1200kg

- Raw material: rice bran, Almonds

Refined Sunflower Seed Oil sunflower seed oil refining process. Sunflower oil refining methods can be roughly divided into the mechanical method, chemical method, and physicochemical method. The operation of the sunflower oil refining machine is divided into the following four steps. 1.

What is an industrial sunflower oil refining machine? An industrial sunflower oil refining machine ( cooking oil refinery equipment) is developed to meet the needs of various edible oil processing plants to refine sunflower seed oil and other kinds of cooking oil. Such equipment can produce fourth-grade oil, third-grade oil, second-grade oil, and first-grade oil. What is the processing