Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 80-5000kg/h

- Voltage: 220V380V

- Main components: motor, pressure vessel, PLC

- Weight: 300 KG

- Dimension (L*W*H): 1.2 *0.78*1.1 m

- Country: mozambique

Cost of Sunflower oil extraction machine: Cost of automatic Sunflower oil extraction machine approximately, Rs 1.45 Lakh/Piece. Benefits of Sunflower oil. May enhance oral health. Sunflower oil is extremely useful for oil pulling. Sunflower oil reduces plaque-related gingivitis.

How Is Sunflower Oil Made? (The Step-by-Step Process)

- Type: sunflower oil processing machine

- Production capacity: 100%

- Voltage: 380 V

- Weight: changed with capacity

- Dimension (L*W*H): various with capacity

- Power (W) : according to capacity

This process involves using chemical solvents to extract the oil from the sunflower seeds. After the oil is extracted, it is filtered and processed to remove impurities. Solvent-extracted sunflower oil is usually lower in quality than cold-pressed oil, as the solvents can damage the oils beneficial compounds.

Solvent extraction is the part of the sunflower oil making process in which almost every last drop of oil is extracted from the sunflower seeds. Hexane is the most widely used solvent for this. The process begins with the pouring of hexane over the leftover cake from expeller pressing.

From Seed to Bottle: How Sunflower Oil is Produced in Factories

- Usage: sunflower oil

- Main components: Motor

- Power source: Electrical

- Power: NA

- Voltage: NA

- Process: Vacuum distillation

This extraction process can be done using mechanical pressing or a solvent extraction method, where a solvent like hexane helps release the oil from the seeds.Once the oil is extracted, it

The solvent extraction process utilizes a solvent that diffuses into the prepress cake granules. The extraction process is a complex combination of several mechanisms including leaching, washing, diffusion, and dialysis (Johnson, 1997). Leaching and washing remove oil that is free and easily accessible to the solvent.

The Pre-Pressing and Solvent Extraction Process for Sunflower Oil

- Type: cooking oil extraction machine

- Product type: Wood oil

- Packaging: Bulk

- Processing type: Cold pressed

- Purity (%): 1000

- Volume (L): 125

Single pressing or extraction cannot fully extract the oil in one go, so large edible oil processing plants often choose a pre-pressing and extraction method to produce sunflower oil. This process requires the use of pre-treatment equipment, pre-pressing equipment, complete solvent extraction equipment, and refining equipment as the main

Here are the ten most frequently asked questions (FAQs) about the sunflower oil extraction process, quality, and applications, along with their answers: 1. What is the best extraction method for sunflower oil? Mechanical pressing and solvent extraction are the most common methods used for sunflower oil extraction.

HOW IS SUNFLOWER OIL EXTRACTED? - Grainvest

- Raw Material: sunflower

- Production capacity: 1-100T/D

- Power ( W): different

- Place of Voltage: 220V-480V

- Dimension (L*W*H): 430*230*350

- Weight: 1050 KG

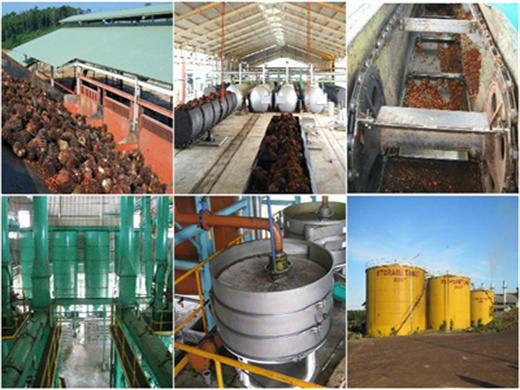

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning; De-hulling; Grinding; Pressing

4. Use sunflower oil pre-pressing machine to obtain a part of sunflower oil form sunflower seeds. Sunflower oil solvent extraction plant: Machines used in sunflower oil solvent extraction plant. 1. Sunflower cakes are sent into extractor, then soaked in solvent, at last the mixed oil will flow out of the extractor. 2.