Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil plant

- Usage/Application: sunflower

- Production capacity: 10-3000 TPD

- Voltage: 380V 440v

- Weight: Depends on the price of cooking oil mill production

- Dimension (L*W*H): As price cooking oil mill capacity

- Power (W): As cooking oil mill at daily production price

- Country: zimbabwe

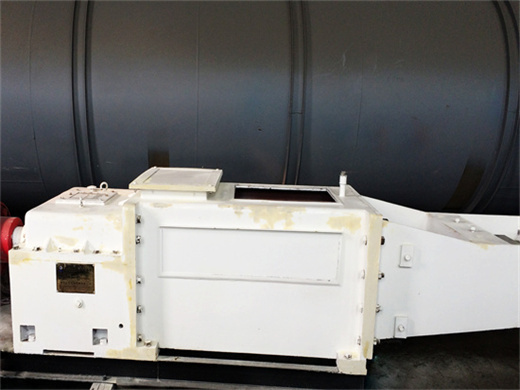

The solvent extraction procedure uses hexane or other solvents to wash the sunflower oil from the prepared flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth required to efficiently wash the flakes, the contact time of the solvent and flakes and the power and utilities desirable to run the

Sunflower Oil: Properties and Manufacture - Kumar Metal

- Type: sunflower oil processing machine

- Production capacity: 100%

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Power (W): 18.5 KW/T

Hexane is passed through the expeller oil cake or meal to obtain a mixture of oil and solvent called miscella. Solvent is removed from the oil and the remaining meal in separate equipments to obtain desolventized sunflower oil and meal. Large capacity solvent extraction plants are used to produce solvent-extracted sunflower oil on commercial scale.

Solvent extraction is the part of the sunflower oil making process in which almost every last drop of oil is extracted from the sunflower seeds. Hexane is the most widely used solvent for this. The process begins with the pouring of hexane over the leftover cake from expeller pressing.

Sunflower Oil Refinery Plant Process - Oil Expeller

- Usage: sunflower oil

- Main components: Motor

- Arc current: standard

- Nominal duty cycle: standard

- Pilot arc current: standard

- Pulse frequency: standard

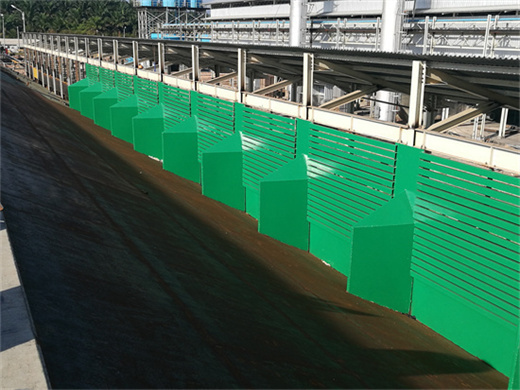

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

This method is less expensive and produces a higher-quality oil. Solvent extraction: Use a solvent such as hexane to extract oil from the seeds. This method is more expensive but produces a higher yield. Crude Oil Refining **Step 3: Crude Oil Refining** Crude sunflower oil contains impurities such as dirt, sand, and gums.

How Is Sunflower Oil Made? (The Step-by-Step Process)

- Type: cooking oil extraction machine

- Production capacity: 1-2000TPD

- Power (W): 5-100kw

- Voltage: 220/380/400v

- Dimension (L*W) *H): depends

- Weight: depends

The quality of the oil depends on the quality of the seeds and the method of extraction used. Cold-pressed sunflower oil is generally regarded as the highest quality, as it retains all of its beneficial compounds. On the other hand, solvent-extracted sunflower oil is usually lower in quality, as the solvents can affect the oils beneficial

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

Sunflower Seed Preparation and Oil Extraction - ScienceDirect

- Raw Material: sunflower

- Voltage: 380v

- Main components: motor, gear, bearing

- Weight: 620 KG

- Oil Raw material: Oil seeds

- Function: Oilseed Press

Prepress solvent extraction relies on exerting medium pressure on the prepared seed to separate the majority of the oil, followed by solvent extraction to separate additional oil from the solids fraction, recovering over 40% oil from the seed in modern crushing plants. Because sunflower oil has a substantially higher economic value than

Figure 3 is a simplified layout of an extraction plant. Figure 3. Solvent extraction – distance diagram. Reference NFPA-36, (2009 simplified). The Solvent Extractor. Percolation Extractor: At the center of the extraction plant is the extractor. A percolation-type extractor is by far the most commonly used for the removal of oil from oilseeds