Turnkey Project of Palm Oil Mill Plant | Lingfine Machinery

- Type: palm oil project

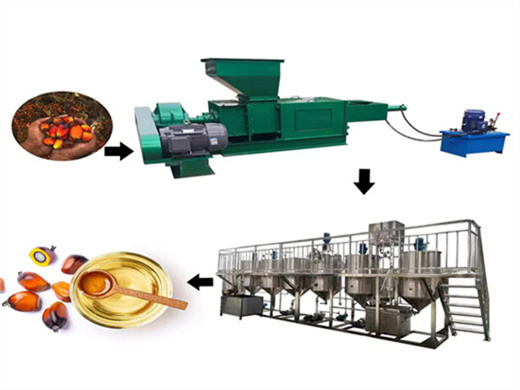

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-50 kg/h

- Voltage: 220 V 50 Hz

- Function: Make Edible Oil

- Raw Material:Oilseeds

- Dimension (length x width x height): 460 x 160 x 350 mm Weight: 13 KG Main components: Engine Oil type: Flax seed, Rap seed oil, Tea seed oil, SESAME OIL, Pine nut oil , Sunflower Seed Oil and Walnut

- Country: afghanistan

7.Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes. Palm oil refining production line of palm oil mill plant

Bulk Oil Storage of Palm Oil Mill Plant|Turnkey Projects

- Type: palm oil processing machine

- Production capacity: 3 tons/day

- Voltage: 380 V/440 V

- Main components: Gearbox

- Weight: KG

- Dimension (L*W*H): Depends

Prevent microbial growth by drying before storage. Low moisture content can prolong the shelf life of palm oil. Choose proper method and tank to store the bulk palm oil after extraction to slow down rancidity. Successful Palm Oil Mill Projects. The following are some onsite photos of our palm oil milling projects.

Complete Oil Plant And Machinery for Turnkey Projects We provide comprehensive oil plant machinery for turnkey projects, offering end-to-end solutions for oil extraction and refining. Our high-quality, reliable machinery is designed to optimize production and efficiency, ensuring seamless operations for various oil types.

Our Businesses – EcoScience | Leading Constructor of Palm Oil

- Usage: palm oil

- Production capacity: 1-100T/D

- Voltage: 380V/440v

- Weight:Depends on capacity

- Dimension (L*W*H )):Depends on capacity

- Power ( W): 20-50KW

We undertake turnkey projects in building biogas plants for palm oil mills to generate biogas from palm oil mill effluent (POME). OLEOCHEMICAL PLANT Ecoscience develops oleo-chemical plants and provide equipment installation due to the rising of demands of commodities such as fatty acids, glycerine and esters.

Each of our oilseed engineering lines has a capacity to process a range of 100-8000t/d oilseeds. We can provide turnkey projects for soybean oil, rapeseed oil, tea seed oil, cottonseed oil, corn germ oil and palm oil.

Faq of edible oil turnkey project - Huatai Oil Machinery

- Type: cooking oil extraction machine

- Production capacity: 65-130 kg/h

- Voltage: 220/380 V

- Main components: Gear, cooking oil making machine

- Weight: 880Kg

- Dimension (L*W*H): 1500 *1300*1550mm

Frequently asked questions about our factory and oil processing equipment. Why choose Huatai? Huatai machinery has developed projects including large scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project,conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology

Below shows the flow diagram of dry degumming process of palm oil refining. Degumming Process of Palm Oil Refining Plant. Dry degumming process of palm oil: For crude palm oil refining plant, drying degumming process is suggested. Classically, crude palm oil is first mixed with about 0.05– 0.1% concentrated phosphoric acid.

Palm Oil Mill Turnkey Projects - Sawipac

- Raw Material: palm

- Material: NIP90 Antipulping Coated, NIP90 Antipulping Coated

- Color: Four-color process

- Industrial use: Beverages

- Features: Perfect printing

- Size: Customized

We also undertake mill upgrading works for palm oil mill. Our Innovative CKD Manufacturing Approach in delivering engineering solutions reduces construction period for a 60 TPH palm oil mill from 18 months to 13 months.

We Manufacture and supply Turnkey projects for Edible Oil Refining plants From 10tpd to 500 tpd, We support Customers from Concept to commissioning for Designing, Layouts for Plant and Equipment, and Utilities. We Offer Complete solution in Edible Oil Refining Packing and By-products Processing into Value added Projects.