Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil refinery machine

- Usage/Application: cottonseed

- Production capacity: 35-11000 kg/h, 30 ~ 70 kg/h

- Voltage: combined with local voltage

- Weight: According to the model of oil press in china

- Dimension (L*W*H): According to the model of oil press in china

- Power (W): According to the capacity of the oil press in china

- Country: uganda

Cracking: Adopting the toothed cracking roller to make the cotton seeds kernel into a right uniform pcs which can keep a moderate block size for squeezing out the oil. Flaking: To make cracked Cotton seeds kernel pcs into uniform smaller flakes with thickness ≤ 0.5mm, less powder, non-oil spilled, pinching softly by hand and the ratio of

Cottonseed Oil Mill Plant

- Type: cottonseed oil refinery machine

- Voltage: 380 V

- Power (W): 5.5 ~ 11 kW

- Certification: CE ISO

- Weight: 1200 kg

- Dimension (L*W*H): 1700 *1100*1600 mm

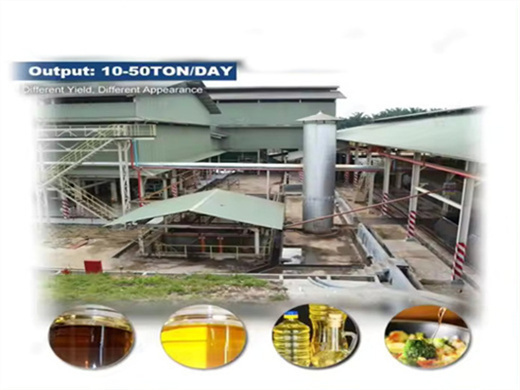

Fractionation and Refining Crude Cottonseed Oil. 30ton/day Cottonseed Oil Refinery Plant. Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization.

Main Steps of Cotton Seeds Oil Refining. 1. Crude Oil Degumming. In this step gum in crude oil is removed by hydration with the help of phosphoric acid. 2. Neutralization. In this step, free fatty acids are neutralized by using sodium hydroxide and converted into soap. Additional impurities are also removed by adsorption of the soap. 3. Bleaching.

Top-rated cotton seed oil making machine | cottonseed oil

- Usage: cottonseed oil

- Production capacity: 1-500T/D

- Voltage:220V/380V/440V

- Weight:1050 KG

- Dimension (L*W* H):430*230*350

- Power ( W): According to capacity

A cold cotton seed oil press is an oil extraction machine that uses hydraulic oil to pressurize and transmit pressure through an oil pump. The cold-pressed cottonseed oil has good oil quality, high oil yield, does not generate temperature during the cold-pressing process, does not destroy the organic components of the oil, and contains fewer

Except these six listed impurities, there are also some other special element contained in some kinds of oil, such as gossypol in cotton seed oil and mustard glycosides in rapeseed oil. Some of them not only affect the quality of oil products, but also harmful to human health. So it is essential to remove them by use of oil refinery plant.

Factory Price Cotton Seed Oil Mill Machine for Sales | ABC

- Type: cooking oil refining machine

- Production capacity: 5-500 TPD

- Weight: 500 TONS

- Voltage: 440 V

- Certification: ISO,CE

- After-sales service provided: Engineers available to service machinery abroad.

Cotton Seed Oil Processing Machine (1~20T/D) Different from traditional screw oil press, our cotton seed oil machine is available with heating device. Therefore, you have the choice to save preheating time of the machine itself. More importantly, it can greatly improve the oil output as well as quality of crude cotton seed oil.

So ,that’s the purpose of oil refining. Preparation Before Crude Oil Refining. The operation conditions are different according to different kinds of crude oil, the following operating instructions are only for reference. Crude Oil Test: Determine the acid value and color. If conditions permitting, do a small sample experiment in the laboratory.

Complete Cotton Seed Oil Processing Plant

- Raw Material: cottonseed oil

- Production capacity: 5 tons to 100 tons per day

- Dimension (L*W*H): According to production capacity

- Voltage: 380 V

- Weight: 10000 KG

- Main components: motor, pressure vessel, pump, bearing, motor

Cottonseed Oil Cake: the product of cotton seed being extracted the residual oil and can be used as protein in feed production; The complete cotton processing plant has a series of process, including delintering, dehusking, oil pressing, solvent extraction for oil, oil refining and more.

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company; What is a comprehensive guide to setting up the best cpo refinery plant? The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda