Cottonseed Oil Processing Plant | Extraction Flow

- Type: cottonseed oil extraction machine

- Usage/Application: cottonseed

- Production capacity: 100% cooking oil extraction machine

- Voltage: 220V/380 V/440 V

- Weight: 50tons

- Dimension (L*W*H): 48m*12M*15M(50tons)

- Power (W): 5.5-22KW

- Country: nairobi

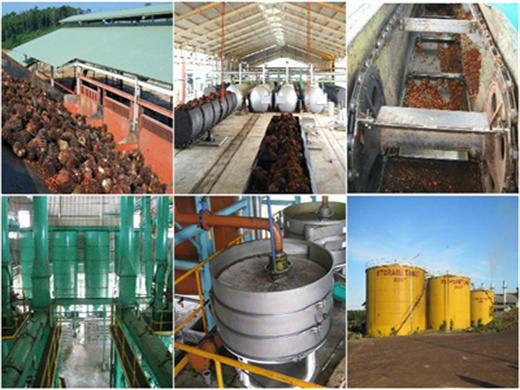

The traditional cottonseed oil extraction process involves pressing or extraction. The common cottonseed oil processing flow: cottonseed - cleaning - shelling - shell kernel separation - embryo rolling - high moisture steaming - pre-pressing - solvent extraction. Cottonseed oil contains a large amount of essential fatty acids, among which

Production of Cottonseed Oil - Edible Oil Expeller Machinery

- Type: cottonseed oil processing machine

- Production capacity: 100TPD

- Voltage: 380V

- Main components: Others

- Weight: 1300 KG, 1300 kg

- Dimension (L*W*H): 800*650 *1100 mm

The residual oil in the oil can be controlled below 1% under the extraction method. 2.The quality of the meal is good. 3.Low processing cost and low labor intensity. Classification of cottonseed oil extraction equipment: Immersion type: tank group extractor, u drag chain type and Y type extractor. Spray type: crawler extractor. Hybrid: flat

Technology Flowchart of Cotton Seed Oil Production Cotton seed → Delinting → Shelling → Flaking → Extrusion → Extraction → Mixed Oil → Steaming (mixed oil concentration 65-70%) → Acid reaction → Alkali reaction → Heating → Centrifugal separation → Twice steaming → steam stripping → Cottonseed oil neutralization → Decolorization → Deodorization → Refined

Complete Equipment and Machinery for Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Production capacity: 30-600 kg/h

- Voltage: 220 V/380 V

- Main components: Motor

- Weight: 260KG

- Dimension (L*W*H): 1980*680* 1460mm

The solvent extraction process is to use the organic solvent to extract oil from the oil seeds, the press process is to use the mechanical pressure to press the oil from the oil seeds. The two different points between "pressing process" and "solvent extraction process" are the oil yield and the cost. When taking the pressing process, the

The crude cotton seed oil and cottonseed cake can be obtained after being processed by the cottonseed oil pre-press. The cottonseed cake is transported to the leaching workshop to further produce cottonseed oil. In the process of cottonseed oil extraction, the cottonseed cake and the solvent are contacted first, so that the oil in the cake

Cotton Seed Oil Extraction Machine Plant for Small Solvent

- Type: cooking oil extraction machine

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Main components: Gear, Bearing, Gearbox

- Weight: 500 KG

- Dimension (L*W*H): According to the equipment

Cotton seed oil can be generally divided into expeller-pressed oil, solvent extracted oil, crude oil and refined cottonseed oil. Cottonseed oil is dark red in color, and it is edible after refining. It contains a lot of essential fatty acids for human consumption, and it is also good to be mixed with animal fats.

Machinery and equipment required to start Cotton Seed Oil. When establishing an entire cottonseed oil extraction plant, you should consider the process design and equipment choice into account. It is crucial to check the pros and cons of the processing technology and machinery.

Solvent Extraction Plant Technology and Equipments

- Raw Material: cottonseed oil

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 1700*1100*1600mm

- Voltage: 220V/380V

- Weight: 1200 KG

- Main components: motor, motor

Cotton Seed Solvent Extraction Plant: Cotton seed oil is a cooking oil which extracted from the seeds of cotton plant of various species. An undelinted seed composition is about:8-10% of lint, 18-22% of oil, 30-35% of meal and 30-35% of hulls.

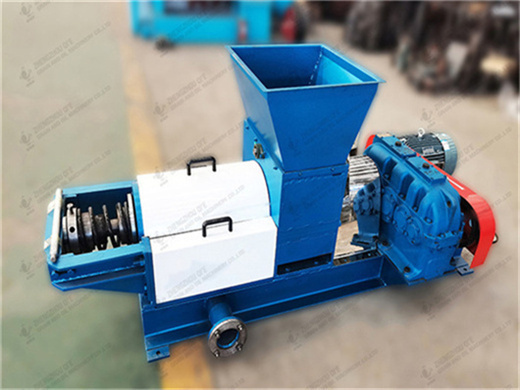

Oil Extraction: After pretreatment, the material is transported to the oil pressing workshop, where the pretreated materials are transported to the cottonseed oil expeller to squeeze the oil out. The whole cottonseed oil extraction process may need several times to ensure the high oil output.