Top-rated cotton seed oil making machine | cottonseed oil

- Type: cottonseed oil press machine

- Usage/Application: cottonseed

- Voltage: 380V/220V or as required

- Dimension (L*W*H): 2700*820*1400mm

- Main components: Motor

- Main components warranty: More than 5 years

- Weight: 1800KG

- Country: botswana

A cold cotton seed oil press is an oil extraction machine that uses hydraulic oil to pressurize and transmit pressure through an oil pump. The cold-pressed cottonseed oil has good oil quality, high oil yield, does not generate temperature during the cold-pressing process, does not destroy the organic components of the oil, and contains fewer

Hydraulic Oil Press & Screw Oil Press Machine For Sale - Buy Now

- Type: cottonseed oil processing machine

- Production capacity: 100%

- Voltage: 220V/380V

- Weight: 600 kg -1600 kg

- Dimension (L*W*H): 1700* 1100*1600 mm

- Power (W): 5.5 kw-15 kw

Cotton Seeds Oil Press Machine: Cottonseed oil extraction involves a series of steps, including delinting, dehulling, and flaking of the seeds. The flaked seeds are then subjected to high-pressure screw pressing to extract the oil, which is further refined to improve quality and stability.

The automatic oil press machine is a popular oil extraction machine in the edible oil production and processing market.The reason why the multifunctional automatic oil press has become the choice of edible oil manufacturers and investors is precisely because of its low investment cost and high squeezing efficiency.

Seed Oil Press Machines for Sale-Industrial Oil Press

- Usage: cottonseed oil

- Production capacity: 1-2000TPD

- Voltage: 220V

- Weight: 1300kg

- Dimension (L*W*H): 46*32 *36cm

- Power (W): 5.5 kW

Use the electric motor or diesel as engine; high oil output,qualified oil,simple design and continuous operation;pressing various oil seeds,such as peanut, soybean,flax seed,cotton seed and so on;labor and energy saving because of the improved design;

The solvent extraction process is to use the organic solvent to extract oil from the oil seeds, the press process is to use the mechanical pressure to press the oil from the oil seeds. The two different points between "pressing process" and "solvent extraction process" are the oil yield and the cost. When taking the pressing process, the

Cotton Seed Oil Expeller for Sale|Premium Quality & Low Cost

- Type: cooking oil extraction machine

- Production capacity: according to capacity

- Power ( W): according to capacity

- Voltage: 380V or 440 V

- Dimension (L*W*H): according to capacity

- Weight: according to capacity

We supply a great number of seed oil making machines including cotton seed oil expeller and automatic oil press for other plant seeds. We also offer turnkey solutions for complete set of oil mill plant, capacity ranging from 1 TPD to 6000TPD. Feel free to tell us your oil manufacturing needs and we will help you make the best plan!

Cotton Seed Oil Processing Machine (1~20T/D) Different from traditional screw oil press, our cotton seed oil machine is available with heating device. Therefore, you have the choice to save preheating time of the machine itself. More importantly, it can greatly improve the oil output as well as quality of crude cotton seed oil.

Hydraulic Automatic Oil Press Machine

- Raw Material: cottonseed oil

- Production capacity: 100TPD

- Power: 3kw*2

- Voltage: 380V

- Dimension (length x width x height): 1300x1050x2200mm

- Weight: 2000kg

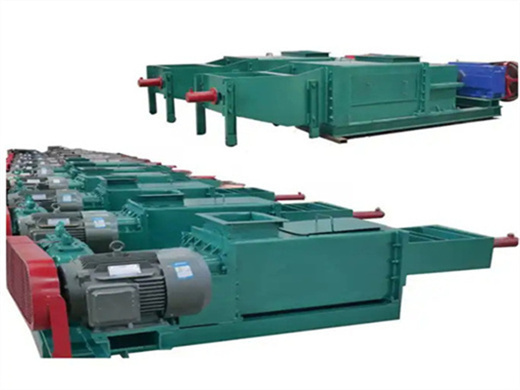

ZY / ZX28 spiral oil press is a large continuous oil press equipment, through the 09001-2000 Quality System Certification, Suitable for cottonseed,rapeseed, castor, sunflower seeds, peanuts and other high oil content of the press oil.It has the characteristics of large processing capacity, small power consumption, low operating cost, loose and not broken cake structure, easy solvent

The YZS series automatic oil press is an advanced cotton seed oil extruder which is developed on the previous single oil press machine according the market demands. It has strengthen the function of frying and automatic controlled temperature, which has changed the traditional way for increasing dry cake's temperature, therefore it reduced the working time, and also reduced the waste of power