Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil processing plant

- Usage/Application: sunflower

- Voltage: 220V/380V

- Power (W): 15KW

- Production After-sales service: Yes

- Weight: 1300kg

- Dimension (L*W*H): 2200*1600*2150mm

- Country: johannesburg

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

High-Efficiency Sunflower Oil Extraction Machine

- Type: sunflower oil processing machine

- Production capacity: 140-280kg/h

- Voltage: 380V/415/440V

- Warranty: 1 year

- Weight: 1000 KG

- Dimension (L*W*H): 1800*1300*1680

Oil processing enterprises: For enterprises that produce sunflower oil on a large scale, leaching extractors are the first choice. This machine can efficiently and quickly process a large number of sunflower seeds, extract high-purity sunflower oil, and meet the needs of large-scale production. Small and medium-sized processing plants: For

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

Processing Edible Oils - Penn State Extension

- Usage: sunflower oil

- Voltage: 220 V

- Dimension (L*W*H): 1.96*1.25*1.67 m

- Oil type: cooking oil

- Main components: gearbox, pressure vessel, pump, gear, bearing, motor, motor, PLC

- Weight: 650 KG

In a typical edible oil processing plant, oil is extracted from the seed first using mechanical extraction (expeller press) followed by chemical extraction (hexane extraction). By using both methods, less than 1% of the oil is left in the meal that is produced. The majority of this meal is sold for use in animal feed rations. Components of

4. Use sunflower oil pre-pressing machine to obtain a part of sunflower oil form sunflower seeds. Sunflower oil solvent extraction plant: Machines used in sunflower oil solvent extraction plant. 1. Sunflower cakes are sent into extractor, then soaked in solvent, at last the mixed oil will flow out of the extractor. 2.

Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: cooking oil extraction machine

- Press Materials: Oil Crops

- Custom: Custom

- Press Series: Second

- Capacity: 1-1000 tons

- Advantage: Easy operation

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

Multifunctional fully automatic commercial use sunflower oil expeller; D.T.D.C.system in sunflower oil solvent extraction plant; Single screw sunflower seed oil expeller machine; Solvent extractor for sunflower oil extraction plant; Sunflower oil filling machine; Sunflower oil production line; Small scale sunflower seed oil processing plant

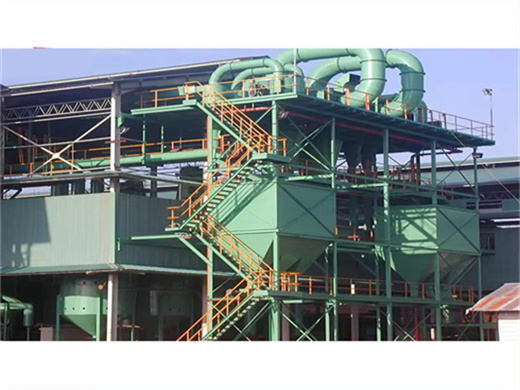

Sunflower Processing, Processing of Oil Seed and None-oil seed

- Raw Material: sunflower

- Production capacity: 100-130T per 24 hours

- Dimension (L*W*H): 4100*2270*3850 mm

- Voltage: 380V/50HZ

- Weight: 11500 KG

- Warranty: 1 year, 12 months

Sunflower Seed Processing. Sunflower seeds come in 2 types: the non-oil seeds that are eaten as confectionery products after roasted with the shell or without the shell as kernels, and the oilseeds that are processed into oil and meal which is a by-product of sunflower seed oil extraction primarily used as an ingredient in livestock feed rations.

Sunflower seed oil pretreatment equipment is essential for large-scale edible oil processing plants as it has a significant impact on subsequent processing operations and the quality of crude oil. Oilseed pretreatment machines can remove impurities, regulate the moisture and temperature of the material, and also break down the oilseeds into