Mini Soybean Oil Extraction Machine Plant in malawi

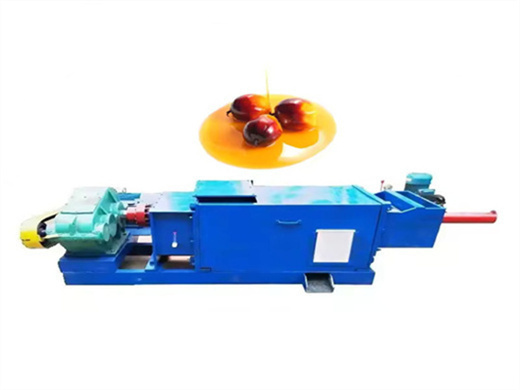

- Type: soybean oil extraction machine

- Usage/Application: soybean

- Production capacity: 300-600 kg/h

- Voltage: 220 V/380 V

- Main components: Engine oil

- Weight: 1500 KG

- Dimension (L*W*H): 1360*780* 1200 mm

- Country: malawi

The small soybean oil processing plant designed by Hongde Machinery, with capacity 5~20 tons per day may need at least $7,500. But the final exact cost should be confirmed with your sales Oil Pressing Process: The cleaned seeds undergo a pre-pressing stage using a screw oil press machine.

BEST Soybean Oil Machine for Sale|Screw Pressing & Solvent

- Type: soybean oil processing machine

- Production Capacity: 10TPD-500TPD

- Voltage: According to customer demand

- Weight: According to customer demand

- Dimension (L*W*H) : According to project

- Power (W ): According to project

The selection of soybean oil processing machine should be closely related with the capacity, oil production process, final soybean oil uses, investment budget and other exact conditions. (Related post: Small Scale Soybean Oil Plant Cost in India >>) Soybean Oil Extraction Machines at Factory Price

Small Scale Soybean Oil Pressing Line. If the processing capacity of soybean oil is less than 10 tons per day, it is only necessary to open a small soybean oil pressing production plant and choose an integrated oil press with automatic temperature control and vacuum filtration to meet the pressing requirements of soybean oil. If the processing

Soybean Oil Process Machine

- Usage: soybean oil

- Voltage: 220 V

- Dimension (L*W*H): 550*200*320 mm

- Main components warranty: 6 months

- Warranty: 6 months

- Weight: 12.5 KG

1. Soybean Oil Press Machines: - These are mechanical screw presses used for squeezing oil from soybeans. They are used in small and medium-scale processing plants. They are easy to operate and offer moderate oil yields. 2. Soybean Oil Solvent Extraction Machines: - These machines use solvents like hexane to dissolve and extract oil from the

Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction. The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed.

Soybean Oil Processing Machine

- Type: cooking oil extraction machine

- Finish: ZINC PLATED, Polished, Custom

- Standard: ISO

- Measurement System: Metric, Imperial (Inch)

- Product Material: Stainless steel Carbon steel or customer's

- Surface Treatment: Plain Zinc or Customer's

1.Soybean Oil Press Machine: Screw Press: Commonly used for cold and hot pressing, this machine uses pressure to extract oil. Screw presses are suitable for small to medium-scale operations. Hydraulic Press: A more traditional method used for high-quality oil with low temperature pressing.

These oil extraction machines gather vegetable oil from oil-bearing seeds and nuts for food and industrial uses, including biodiesel and other fuels. Our durable, heavy-duty oilseed equipment has an average life span of 60-70 years, operating with maximum productivity and lower processing cost per ton. Download our literature on screw presses

How Many Machines Are Needed In A Small-scale Soybean Oil

- Raw Material: soybean

- Production capacity: 50-700T/24 hours

- Dimension (L*W*H)): 2140*550*765mm

- Voltage: 380V/50HZ

- Weight: 580 KG

- Warranty: 1 year, 12 months

The above are small-scale soybean oil production line. If the small-scale soybean oil mill plant has a processing capacity of less than 20 tons, it is recommended to use the above steps. If the processing capacity is large, it is recommended to use more complete soybean oil production machines to obtain more and cleaner soybean oil.

Cooking oil industry is one of the most basic sectors for the developmen of human beings. There are many oilseeds that are suitable for cooking oil processing, like soybean, groundnut, palm kernel, sunflower seeds, cottonseeds, etc. Cooking oils are extracted by a series of oil production processes, the most common cooking oil extraction processes has: