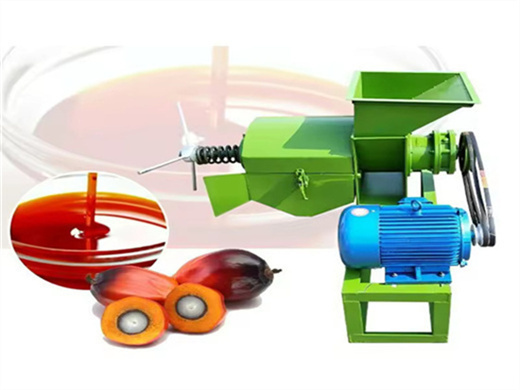

What are the machines used for palm oil processing?

- Type: palm oil extraction machine

- Usage/Application: palm fruit, palm kernel

- Raw material: Seeds

- Available quantity: 100000000

- Service: OEM ODM Private Label

- Features: Skin Revitalizer, Moisturizer, Pore Cleanser, 100% Natural Ingredients

- Ingredient: Rice

- Country: botswana

Palm oil processing machines. 1. Fruit Reception: It is used for temporary storage and unloading fresh palm fruit bunches from palm plantation. Fruit reception. 2. Sterilizer: three types of sterilizers can be chosen in palm oil processing. All use high temperature of 145°C to soften and sterilize the fruit bunches.

Small Scale Palm Kernel Oil Extraction Machine for Automatic

- Type: palm oil processing machine

- Production capacity: 20-2000TPD

- Voltage: 380V

- Weight: standard

- Dimension (L*W*H): standard

- Power (W): Standard

Key Factors of Palm Kernel Oil Processing - Capacity & Process & Equipment. Generally, palm kernel oil processing capacity, palm kernel oil extraction process and palm kernel oil extraction machinery are the key factors to start up palm kernel oil mill plant for business. Usually, the palm kernel oil processing can be divided into mini scale

A full range of palm oil milling equipment, with everything you need for your oil room and (crude palm oil) CPO washing; Reliable palm oil refining process technologies with complete plant solutions for bleaching and deodorizing; Advancements to improve end-product quality while simultaneously boosting capacity, limiting loss and increasing yield

Leave A Message - Palm oil extraction machine

- Usage: palm oil

- Production capacity: according to your request, high oil yield

- Voltage: 380 V

- Certification:ISO9001

- Dimension (L*W*H):1200*400*900mm3 of the oil refinery processing machine crude oil

- Power (W): according to the capacity of the crude oil refinery processing machine

The medium and large capacity of palm oil mill are 10tph,15tph,30tph,45tph,60tph,80tph and 120tph. Normally 100 hectares oil palm plantations can supply the raw materials for 0.5tph palm oil mill, 200 hectares oil palm tree plantations can supply the raw materials for 1tph palm oil mill. You can calculate the capacity of palm oil mill that you

At first, if you want to start small palm oil processing business with small capacity 1-5T/D, meanwhile you prefer stand-alone palm oil press machine to complete palm oil mill factory, you can choose stand-alone palm oil press machine. We have 300-500kg/h,1t/h-15t/h palm oil press machine for your choice.

Palm Oil Processing Production Line

- Type: cooking oil extraction machine

- Production capacity: 10 to 500 tpd cooking oil processing

- Power (W): depends on capacity

- Voltage: 220V/ 380V/440V

- Dimension (L*W*H): 5432*2636*2345

- Weight : 850 KG

There are three common palm oil fractionation temperatures: 18°C, 24°C, and 36°C. Dingsheng Machine adopts the palm oil dry extraction process. The new palm oil extraction complete sets of equipment include new type crystallizing tanks, diaphragm filters, and PLC automatic control systems.

Main Station of Palm Oil Extraction Plant( Whether it is a small scale palm oil machine or large scale palm oil processing plant all include the following station): 1) Palm fruit reception station; 2) Palm fruit sterilizing station; 3) Palm fruit threshing station; 4) Palm fruit digesting & pressing station; 5) Crude palm oil clarification station;

Design and Fabrication of a Palm Fruit Digester - ResearchGate

- Raw Material: palm

- Voltage: 380 V

- Dimension (length x width x height):1910*550*765 mm

- Power: 2.2 KW

- Weight: based on refined oil plant capacity

- Certification: CE, BV, ISO9001

evaluation showing that the machine h as a capacity of 740kg/h. with an efficiency of 92.31%. average throughput and palm oil extraction efficiency of this machine as zero, 204.51kg/h and 97.

Palm Kernel Oil Solvent Extraction Plant is recommended for large Palm Kernel Oil Mill with high capacity. However, For the purposes of small-scale operations it is sufficient to mention the solvent extraction process is an alternative for high capacity mills. However the process is not recommended for small enterprises. Basic Unit Operations